How AI is reshaping a mature industry, advancing efficiency and safety

Artificial intelligence (AI) plays a large role in the modern world. Netflix suggests what you should watch. You can ask Siri how to make a soufflé. While AI is certainly making life easier on the average person, it’s also providing great insights and opportunities for almost every industry.

Mining, an industry that is very mature, has evolved tremendously due to technology. It makes sense that AI would eventually play a role in the world of mining. AI is an area that Bend-tech is richly involved in.

AI algorithms

The mining industry is regularly using machine learning prediction and AI. Algorithms can be devised that provide huge advantages. These algorithms use real-time PI data to automatically warn operators or maintenance teams of downtime way in advance of a problem occurring. The benefits of this are huge. This allows for companies to strategically plan for downtime. It saves time and resources. It can also keep employees safe as it provides a warning.

This is just one application of machine-learning and AI. Another opportunity is the assessment of ore fragmentation. This innovation allows for automatic assessment. It takes less than a minute. The algorithms used assess accurately without being skewed by dark, wet, dusty or humid conditions. Until this innovation, ore fragmentation assessment required an hour and was a manual activity. The future will take these algorithms further, with capabilities to complete geotechnical inspections using 3-D mapping data. The algorithms could be “trained” to recognise spalling, cracked shotcrete or plate deformation. The use of AI to speed up these processes is great but not perfect. The advantage is that it can cover a large area in a short amount of time.

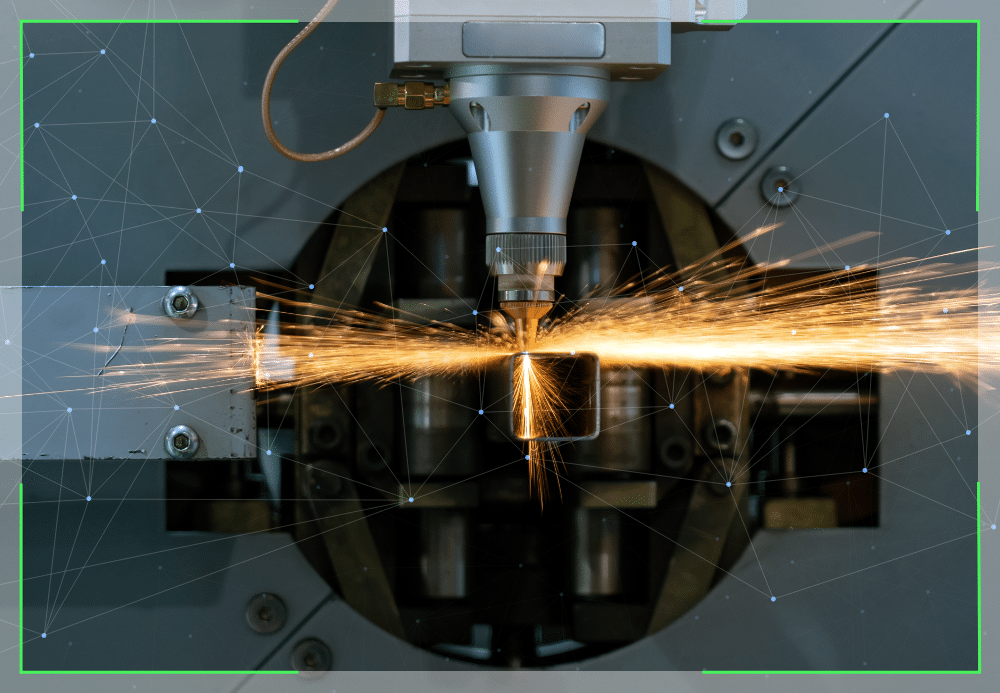

Autonomous equipment

AI is the technology behind autonomous vehicles. While the world isn’t quite ready for highways full of driverless cars, autonomous vehicles used in mining are certainly a reality. Currently, most of the autonomy is limited to vehicles that make repetitive movements. These depend on GPS and RADAR and LiDAR sensors. The evolution of the next AI equipment is on the horizon.

Automation has been and will continue to be an innovation driver in mining. By using industrial vehicles or even robots, the mining industry can reduce costs, improve safety and enhance productivity. Costs can be reduced because the skills required to operate some complex equipment are hard to find. It’s not something a person can learn in a week. In a world of needing to do more with less, mining is looking for opportunities. AI equipment can also go where humans can’t, or in turn would be dangerous to do so.

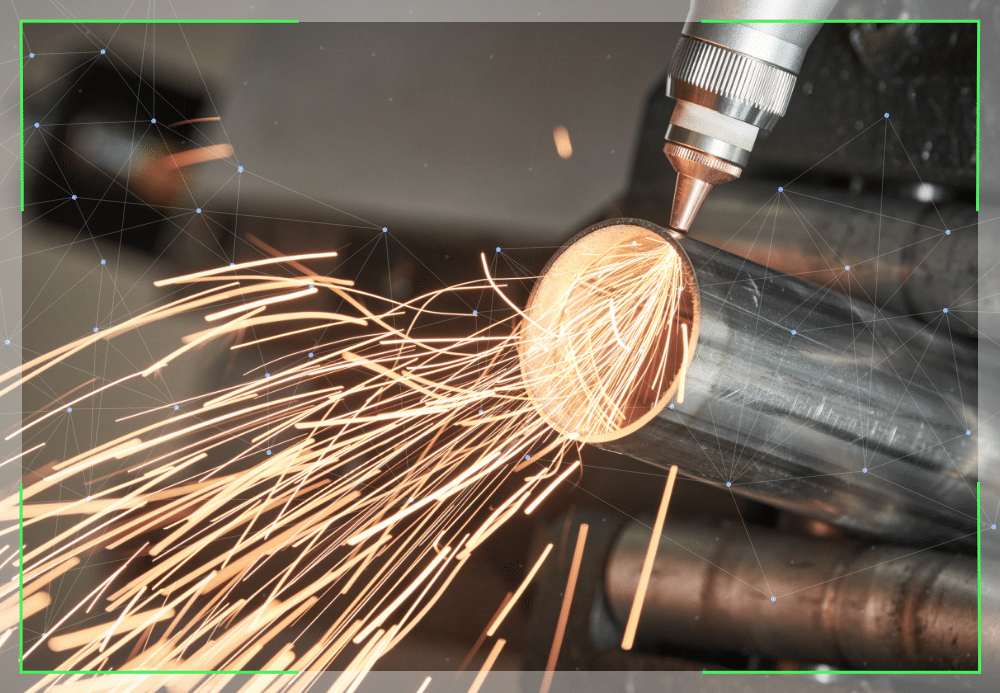

“Smart” equipment and tools

In addition to equipment being able to go where people cannot due to hazards or limitations, there’s also the ability to use drones in mining. Sophisticated drones that are part of an Internet of Things (IoT) can provide real-time information and even sense methane gas. This functionality provides important information about the physical aspects of the mine and its safety.

One application is an innovation that makes drill rigs “smart.” KORE Geosystems installs instruments on drill rigs that can provide real-time, automated data, which can accelerate timelines for many mining stages.

The impact of AI on mining will only continue to grow. As equipment becomes “smarter” and algorithms more sophisticated, the mining industry will have even more reason to use it. Because mining deals with so many things that humans can’t see or smell, machines fill the gap and offer a better process to stay safe and efficient.

About The Author: Jesse Emia

More posts by Jesse Emia