This concise blog will provide an overview of the advantages gained using modern cutting technology over more conventional and long-standing cutting techniques and equipment.

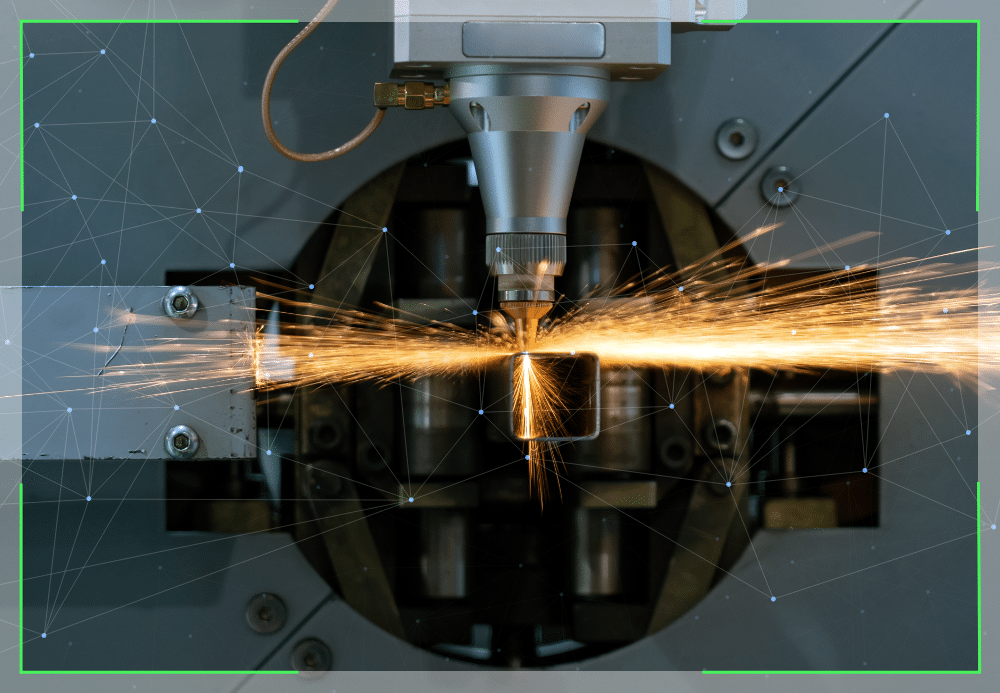

What are tube lasers?

Tube lasers are primarily used to cut tubes, brackets, structural shapes, or channels made from stainless/carbon steel, titanium, or aluminium. They are often used in the automotive industry to facilitate the precision manufacture of exhaust systems. Their ease of use and ability to cut through these awkwardly shaped materials with remarkable precision make tube lasers an irreplaceable tool in any professional metal worker’s arsenal.

Tube lasers vs traditional cutting methods

Traditional methods of cutting pipes and irregularly shaped channels required saws, lathes, shearing, and manual or CNC milling. These methods were used for decades before lasers were developed, and although they were ingenious at the time and alternatives were yet to be available, they have restrictions and disadvantages.

- Saw blades and tools of the calibre required to do this type of cutting are expensive and can break or be damaged.

- Penetrating pipes using traditional methods is not the end of the process. Subsequent drilling and finishing tasks are typically required. These follow-up actions are time-consuming and labour-intensive and often lack accuracy.

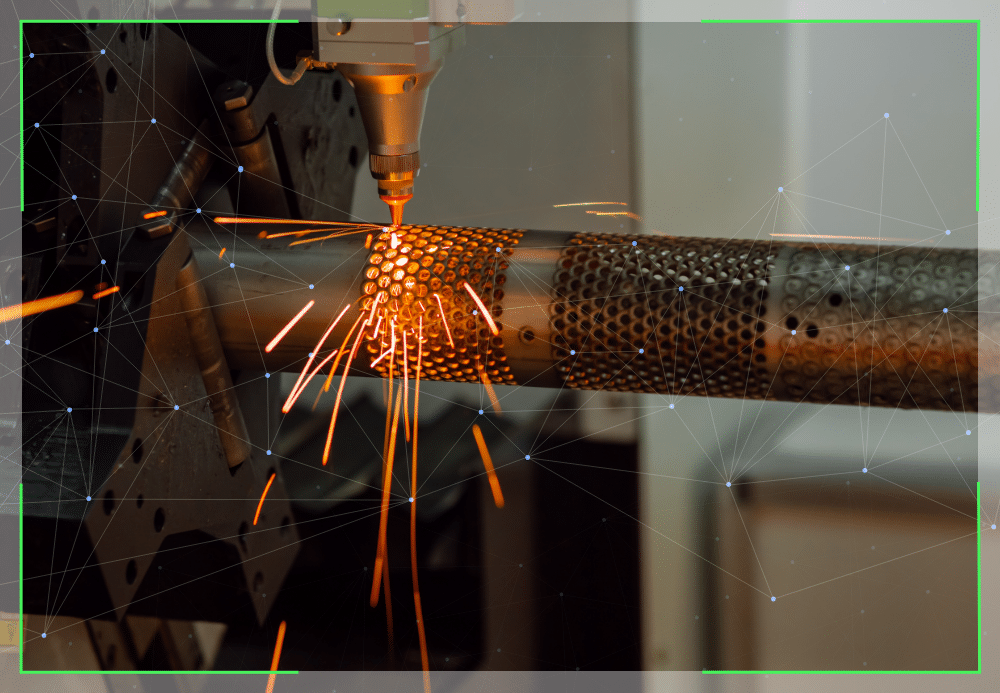

- Laser cutting machines can simultaneously cut, drill, and form piping, eliminating the need for subsequent grinding.

- Precision, speed, and flexibility are all elements of working with lasers that traditional methods cannot emulate.

- Production efficiency dramatically increases when using tube lasers, affecting costs and timings along the manufacturing/supply chain.

Accuracy and fine precision

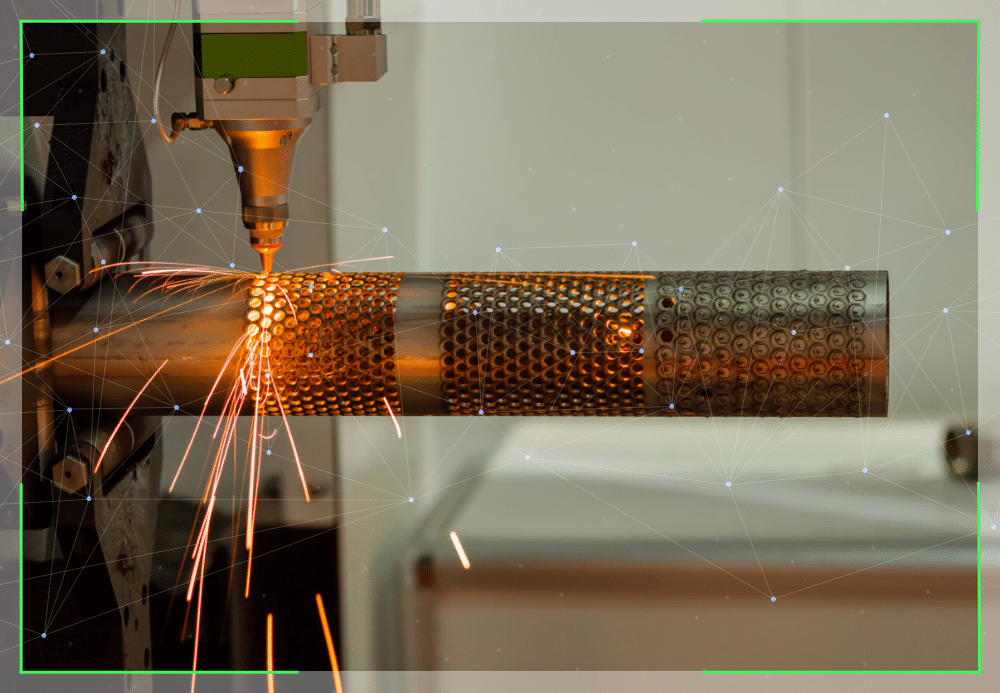

Laser beams are renowned for their capability to make fine, precise cuts, opening the door to a whole range of intricate designs and innovative piping solutions. Connecting surfaces can be machined to very tight tolerances that are extremely difficult to emulate using traditional tube-cutting methods.

Efficiency and speed

For straightforward cuts, lasers are already much faster than traditional methods, yet when we talk of intricate designs and specifications, the gulf between them is astronomical. High-volume manufacturing could not exist in the way it does without laser tube cutting.

Flexibility and versatility

Laser cutting equipment is versatile for various materials, from metals to composites and plastics. Whereas traditional methods require a separate tool for each material, lasers can cut them all precisely and cleanly.

Maximising resources and minimising waste

Extreme precision leads to less waste, a significant advantage for large-scale manufacturers. Traditional methods naturally leave more material on the floor and every gram lost costs money.

Cost and setup times

In the short term, traditional methods have the edge over laser technology because they are faster to set up and less expensive. However, the durability, efficiency, and reduced maintenance requirements of laser equipment mean those savings are met and surpassed in the long run. In addition, removing time-consuming finishing processes and laser technology represents a more astute investment if used repeatedly over several years.

Environmental and safety issues

Laser tube cutting is generally safer than traditional methods. It is a non-contact process, so sharp edges and moving parts are not part of the equation, reducing the risk of injury. Although lasers (especially CO2 models) draw electricity to run, they do not require the toxic lubricants some traditional methods do, and less material is wasted during the process, saving precious resources.

Enhanced design and customisation capabilities

Geometric patterns and intricate designs that can be achieved through laser cutting are almost impossible to recreate using traditional methods. They are the remit of the highest-quality artisans and master craftsmen. The possibilities for customisation and innovative design features when using computer-guided lasers are boundless.

Conclusion

The experts of the past who had no choice but to use traditional methods were genuinely skilled in a way that is almost incomprehensible. Sadly, as time and technology march forward, those skills will undoubtedly be lost. However, they could not hope to match the results that laser-cutting machines can achieve or the speed and accuracy with which they do so. These machines’ sheer volumetric capabilities make them a milestone in the annals of manufacturing history, which virtually kills the timeline of traditional methods as they emerge.

Contact us

If you would like to learn more about tube laser technology and its potential impact on your manufacturing processes, please do not hesitate to contact the Bend-Tech Group team today. Our experienced, knowledgeable representatives are standing by to answer questions, address comments, and assist in any way possible.

About The Author: Highjumpdev

More posts by Highjumpdev