INTELLIGENT DESIGN MEETS CUSTOM ENGINEERING

Our process facilitates your success

Our services deliver custom solutions, certified and compliant with Australian Standards. Designed, engineered and constructed to provide safe, efficient and easy maintenance on-site.

Consultation

We come to you, understand your problem, listen to your requirements, and discuss possible solutions for your project.

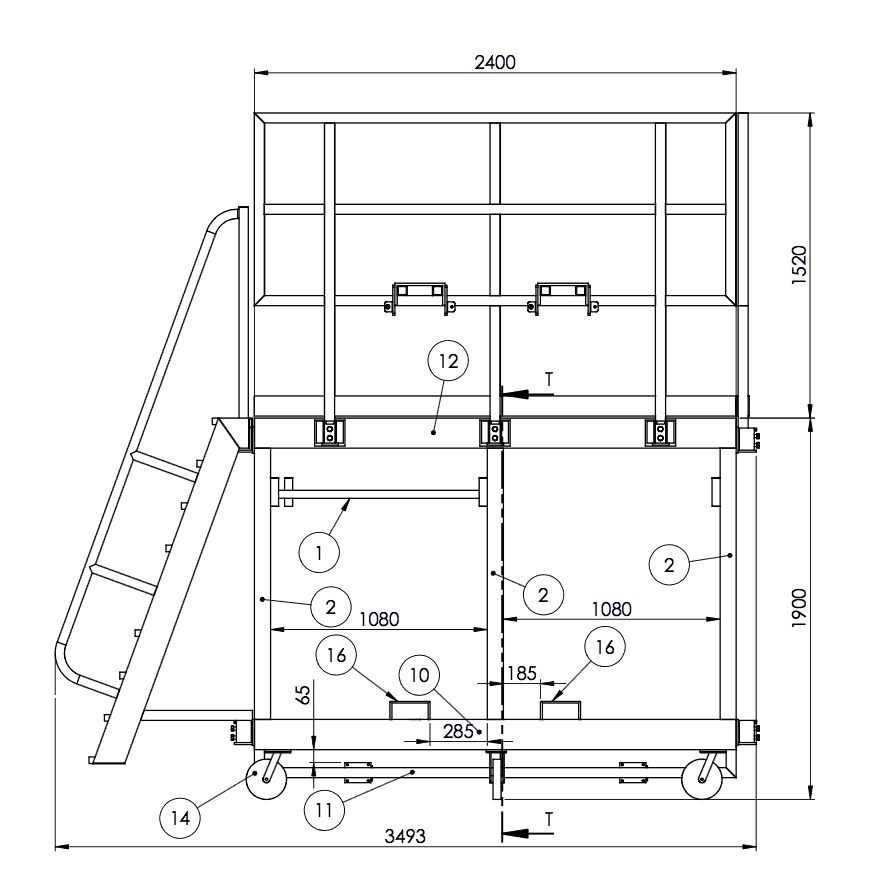

Design

We produce designs in our in-house CAD design division, as well as develop drafting documentation and models for your approval.

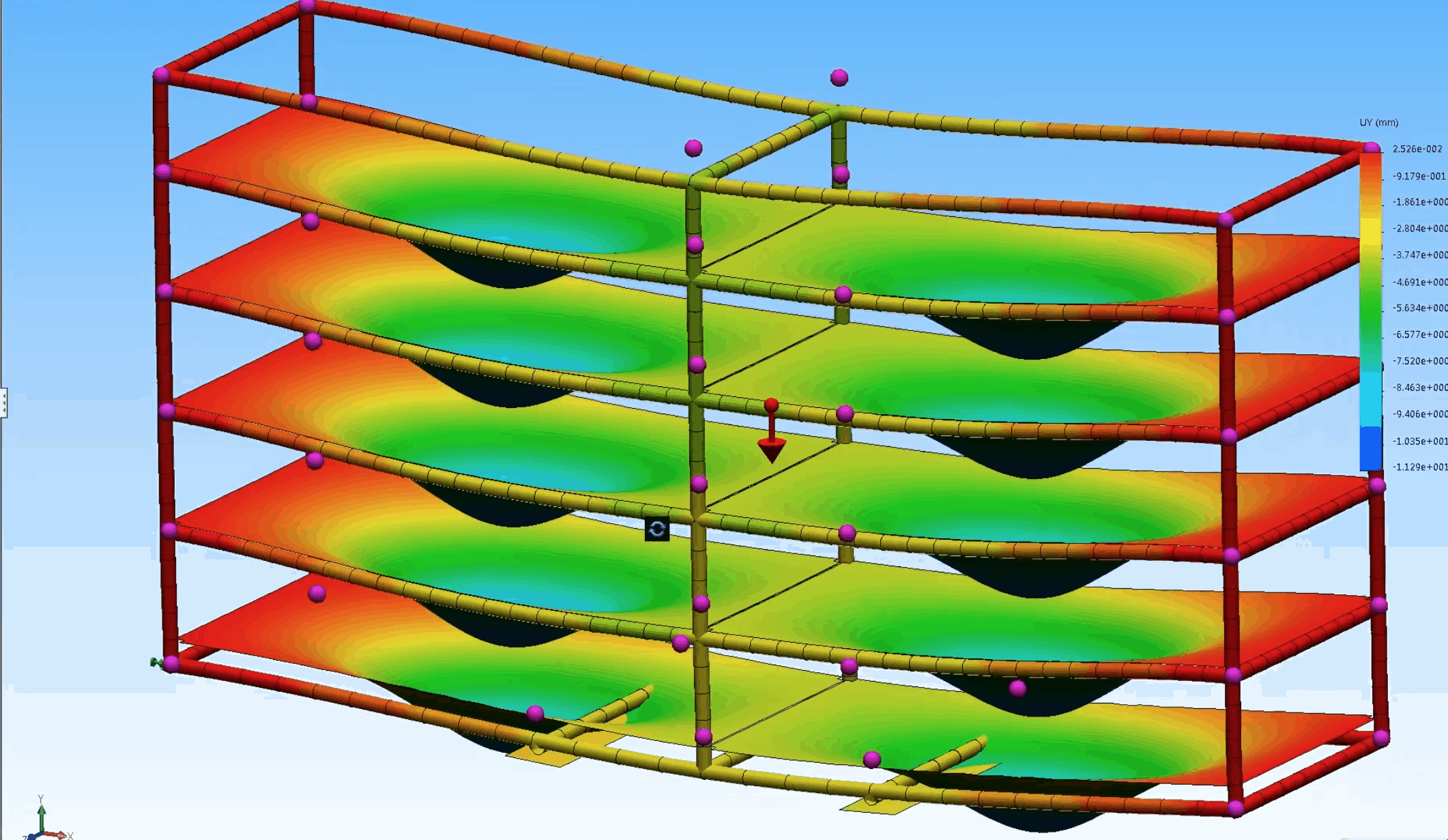

Engineering

We source materials, provide full engineering and certification including WLL, load ratings, integrity reports and certificate plates / identifications.

Construction

We manufacture and include testing, machining, heat treatment, surface treatment and trial fit. Solutions can be delivered fully constructed to site if necessary to minimise down time.

Meet our experienced team

TEAM

Meet our experienced team