Tube lasering, or tube laser cutting, has enjoyed a meteoric rise in numerous different industries, due to its speed and accuracy when cutting stainless steel, aluminium and many other materials. This article delves into what tube lasering is and the many applications and industries where this technology can be leveraged to its full advantage.

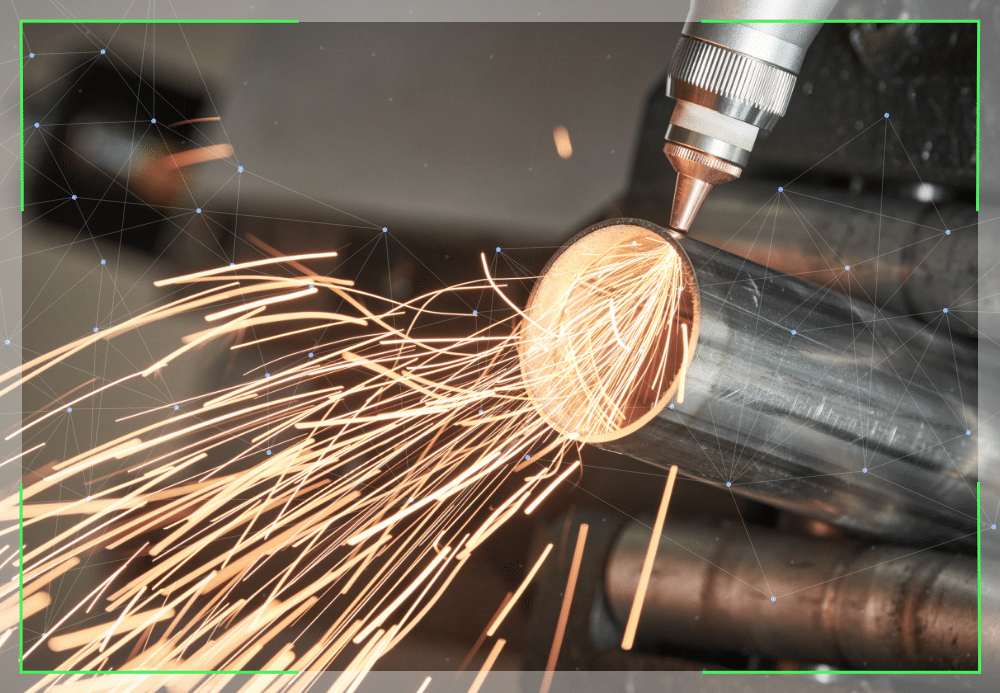

What is tube lasering?

Tube lasering is an intricate cutting machine. Utilising a fibre laser, a tube laser cutter makes short work of cutting through metal pipes, carbon steel and many other materials. With advanced 3D technology, tube lasering can be used to cut objects with complex designs and geometries. No matter what is being cut with a tube laser, it results in a high degree of accuracy with components completed in rapid time.

Let’s now take a look at just some of the industries and applications where tube lasering is a highly effective tool.

Automotive

The automotive industry has a very high demand for parts that are accurately and efficiently produced. The speed and accuracy of tube lasering means that parts can be produced quickly with very little to no variation. Precision in the automotive industry is vital, and that’s where tube lasering excels. Sheet metal body parts and even seat fabrics, can be readily manufactured with a tube laser cutter.

Construction

The construction industry is huge and is responsible for constructing residential and commercial buildings, bridges, tunnels and more. Tube lasering is an essential tool for metal fabrication, the cutting of pipes, steel, base plates, connection plates and many other necessary applications. Major steel construction projects, such as a bridge or commercial building, require thousands of components, and quality laser cutting is the solution to producing them quickly to keep up with demand.

Electronics and technology

Electronic and technical components are readily manufactured with the help of tube lasering. Some key parts include things like heat sinks, brackets, casings and enclosures. As many of these parts are small and need to be precise, a tube laser cutter is perfect for the task at hand. Quality control is assured, parts are produced quickly, and even components with intricate designs can be cut by a tube laser.

Furniture manufacturing

The precision of rotary laser cutting makes it ideal for furniture manufacturers. This enables makers to design and create unique pieces and produce custom-built furniture to the buyer’s exact specifications and vision. With laser cutting technology, furniture creators can produce designs that simply weren’t possible in the past with more traditional methods. Now, the sky’s the limit when it comes to how many unique pieces of furniture can be crafted.

Food service industry

High-quality stainless steel is essential in any commercial kitchen. It’s durable, easy to clean and very hygienic. The use of tube lasering to cut the components for a custom kitchen build ensures the project meets all specifications with extreme accuracy. It’s an ingenious solution that enables components to be produced cost-effectively.

Aerospace

The aerospace industry is an interesting one, and it’s a field that requires components that can withstand extreme pressure for extended periods. To this end, manufacturers rely on tube lasering to produce parts like lightweight aircraft tubing, wing assemblies, hydraulic systems, jet engine components and various other aircraft parts. Even the smallest mistake in this industry can have catastrophic results, so precision in cutting and crafting materials is essential for safety.

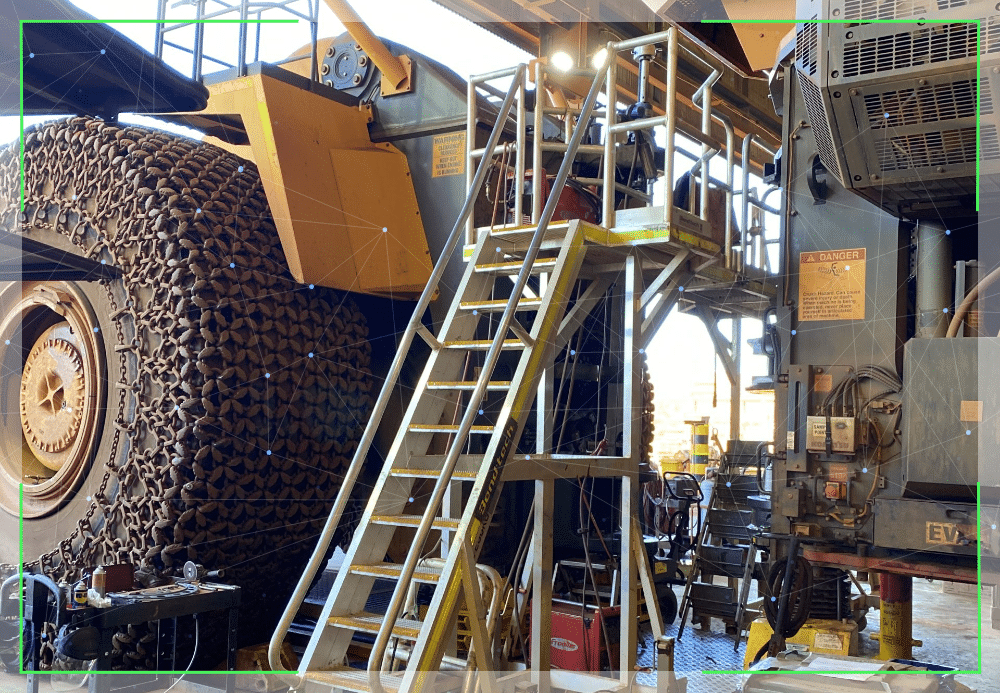

Agriculture

Modern agriculture relies heavily on machinery to harvest food in high volumes to meet demand. To produce these machines, tube lasering plays a crucial role in the development of a variety of parts, and excels at cutting slots and holes in pieces of metal. Even giant storage tanks are crafted with the help of tube lasering.

Fitness equipment

The manufacturing of fitness equipment is another industry that relies heavily on the precision and speed of tube lasering to craft parts and components for weight lifting racks, treadmills, elliptical machines, benches and so on. A lot of metal tubing is used to construct fitness equipment and this is where tube lasering technology is really in its element. Tubes fit together seamlessly and the results are sturdy and robust pieces of equipment.

Precision tube lasering services

For the very best in tube lasering services, you can count on Bend-tech Group for fast and precise cutting services for your project. Our tube lasering capabilities include a 5-Axis Tube Laser and 3D cutting technology for those intricate jobs. Contact us today and tell us about your project.

About The Author: Highjumpdev

More posts by Highjumpdev