Sometimes referred to as scaffolds or staging, work platforms are structures that allow workers and individuals who need access to reach elevated heights and stay there safely to perform any required actions. They are often found in industrial settings but are also used extensively by tradespeople such as painters, electricians, etc. Safety access platforms are almost always the best choice for stable, secure working platforms that offer maximum versatility and flexibility.

Not all work platforms are created equal, and the most suitable version for painting a high ceiling might be of little use to a technician in another industry. Above all, the unit you choose must live up to its name and be as safe as possible for anybody who has to mount it. This blog looks at the variety of safety work platforms and the key features you should insist upon before deciding.

Intended use

Before anything else, when setting out to find the perfect safety access platform, it is crucial to understand the exact role it will be expected to play and the functions it will need to perform optimally. That is not to say that some work platforms cannot be used in multiple scenarios, as the small ones especially are easy to move and reposition. However, nothing is more counter-productive than rushing in to buy the first unit that catches the eye, only to realise it does not suit its intended purpose. Some questions to ask yourself beforehand include:

- Does the unit need to operate outdoors?

- Would the ability to hold tools and other equipment be advantageous?

- Will the platform be used to work on electrical devices and live wires? If so, it must be insulated to the required standard.

Each work platform has unique strengths and characteristics, making it better suited to use in alternative situations. The most common types of safety access platforms are as follows:

- Elevating platforms

Designed to reach the highest places and allow individuals to work safely, elevating platforms come in various sizes and shapes. Most run hydraulically or electrically, and the structure typically extends upwards when controlled by the operator. Intersecting beams create a concertina effect, and devices, buckets, or cherry pickers can be mounted on the top. As these units can be attached to vehicles and operated from there, they are incredibly versatile and can be used in many industries worldwide. If you’ve ever seen technicians working on the telephone lines, the chances are they were using a platform of this nature. Insist upon the following features:

- Guardrails

- Non-slip surfaces

- Secure locking mechanisms

- Failsafe locking mechanism (to prevent unwanted drop in height if power fails)

- Height-adjustable platforms

Typically more expansive than the elevated version, height-adjustable safety access platforms offer a much larger working area and are often used for painting and cleaning tasks. As more space is available and tools can be stored, there is much greater scope for taking everything needed and finishing any task quickly and efficiently. They can also support more people at once than their more upwardly mobile counterparts, making them among the most practical and effective safety access platforms. Insist upon the following features:

- Hinged/chain door

- Guard rails

- Rubber floor mats

- Kick plates

- Smooth operation

- Failsafe blocking valve (prevents the unit from dropping if pressure is compromised suddenly)

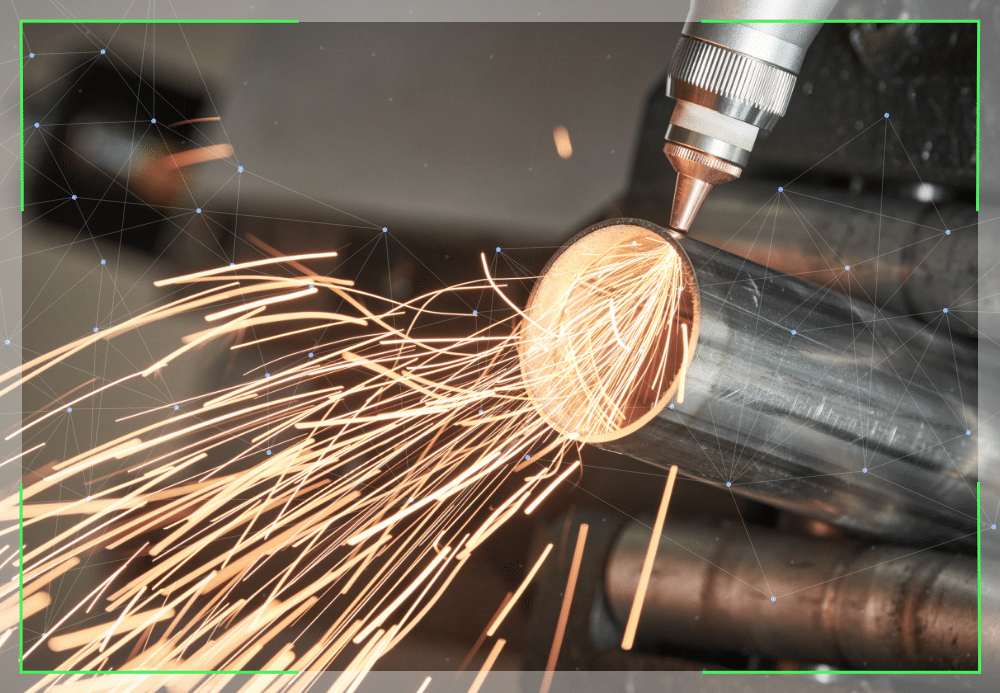

- Maintenance platforms

Perfect for use in industrial settings, maintenance platforms are incredibly strong and stable. They are used for many different tasks, from painting and essential maintenance of large machinery to welding and more. They can withstand enormous loads and are a safe, immovable platform from which to operate. Look for units with the following:

- Guardrails

- Clearly marked weight capacity

- Non-slip surfaces

- Fall protection systems (harnesses etc.)

- Cantilever platforms

The term cantilever refers to these units being unsupported at one end, with the stability produced by contact with the supporting wall or structure. Shelving that sits on metallic arms connected to the wall uses a cantilever system, and the safety access platforms are based on the same principles. Because they can extend above other objects and machinery without requiring support from beneath, cantilever platforms are exceptionally versatile and helpful in reaching awkward, otherwise inaccessible spaces. Features to insist upon:

- Ease of installation and adjustability

- Guard rails and safety features

- Quality needles and brackets

Factors to take into account with safety access platforms

- Height: Determine the maximum height your unit will need to reach and choose your platform accordingly. Although highly flexible and agile, you may need to accept that a platform designed to go extremely high is unlikely to be practical for projects that require extended working areas and storage capabilities.

- Portability and storage: Consider the transportation and storage aspects of your chosen unit. It must be capable of performing the task it is intended for, kept securely when not in use, and transported to the required location when necessary. Balance the platform size and features with your ability to move it around as needed. Look for platforms that can be disassembled (or folded) if you regularly relocate from one job to another. Does the unit require additional moving equipment, or can it be wheeled around?

- Weight capacity: One of the most critical factors is the weight your chosen unit can safely support. This must include the individuals on board, their tools and materials, and any other machinery or items that will be supported. You must never exceed the weight capacity of any safety access platform, as the consequences of doing so can be dire.

Contact us

At Bend-tech, we pride ourselves on designing and engineering the most reliable, durable equipment available anywhere. The equipment will consistently perform above and beyond expectations, even in the most demanding conditions, and conform to all relevant Australian standards. We also provide full backing and assistance with our through-life support services team and are focused on client satisfaction and impeccable standards in everything we do.

When you’re ready to discuss your requirements for a safety access platform, please contact the team at Bend-tech. Our experienced, knowledgeable personnel will offer all the information and advice you need and help you discover our innovative access solutions.

About The Author: Highjumpdev

More posts by Highjumpdev