Mobile equipment maintenance (MEM) refers to maintenance, repair, and servicing of mobile mining equipment such as haul trucks, excavators and wheel loaders. Due to the harsh nature of mining conditions, and round-the-clock usage of mobile equipment, maintenance is an essential every-day practice. MEM involves many aspects, though none are more important than ensuring safe and efficient access to areas that require maintenance.

With some mobile equipment reaching heights of up to 10 metres, it is worth some serious thought in making sure maintenance personnel are using the safest access equipment possible.

Unfortunately, this is not always the case. Traditional access methods usually involve scaffold, which is associated with many inherent risks and ongoing costs such as:

- The requirement for extra non-company personnel on-site

- A minimum of 3 scaffolders needed on-site for a job to build and breakdown

- The hire of the scaffold

- Parts and personnel are not always available

- Scaffold must be regularly inspected and is often not

- Non-inspected scaffolding often left in place due to lack of permanent platform to use a portable access solution

These are just a few of the reasons why sites are choosing to move on from traditional scaffold. To provide further evidence, we completed a cost analysis of one of our customers situations, before and after the use of our access platforms.

The result was an estimated saving of $90,000 in one year, and an ongoing saving of $450,000 considering the platform is still in use 5 years later. (Full cost analysis)

The scaffold elimination process involves a site audit where we scope and inspect existing scaffold that is, or has been erected on a regular basis to access, protect or provide support in a mobile or fixed plant application. If applicable we design, engineer and construct a temporary or fixed solution to completely eliminate the need for scaffold.

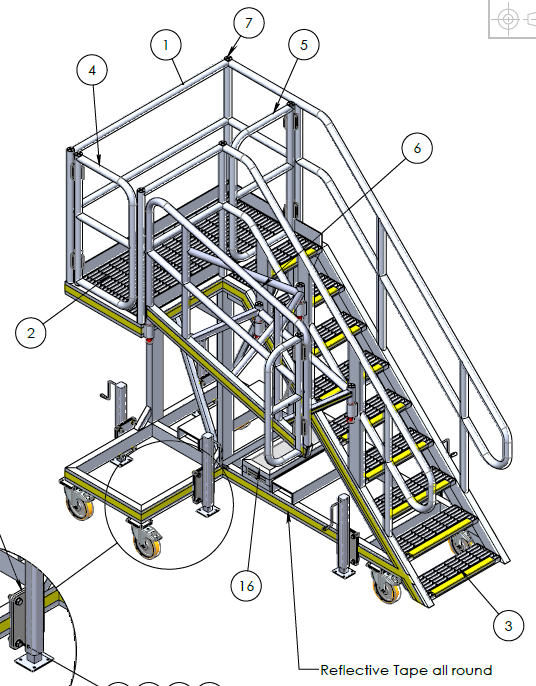

Bend-tech offer a wide range of MEM platforms that are compatible with most truck makes and models, including CAT, Epiroc, Hitachi and Komatsu. All access platforms are designed and manufactured to the highest possible standards and go through a series of quality control tests before Bend-tech release them for sale.

Constructed in heavy-duty aluminium (unless otherwise specified by client) and fitted with high quality German made castor wheels, all platforms are lightweight and easy for anyone to move into position, which speaks to Bend-tech’s commitment to diversity and inclusiveness.

All platforms are fabricated with high performance anti-slip platform and step landings as standard, significantly reducing the chance of slipping. Our TIG welding process is of the highest quality, creating cleaner welds with better penetration and strength to ensure all platforms meet their certified weight load limit.

Our portfolio of MEM access platforms continues to grow with over 100 engineered designs ready for fabrication. To get a better idea about our consultation, design, engineering and construction process, head over to our case studies page and read about some of our recent projects.

Certification and compliance

If you would like to learn more about the benefit certification and compliance can provide and how we can facilitate them for you, download our free whitepaper 10 Valuable Benefits Certification and Compliance Can Add to Your Site or get in contact with one of the team today and discuss your project or problem, we look forward to hearing from you!

About The Author: Jake Marinovich

More posts by Jake Marinovich