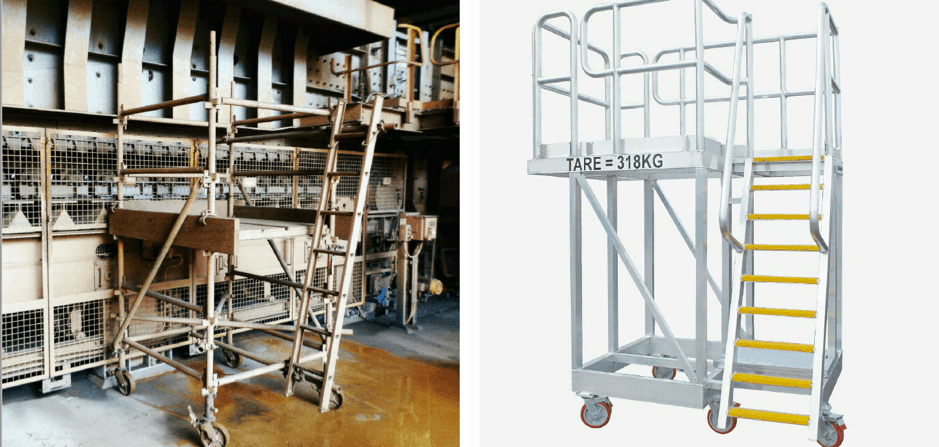

The scaffold elimination process involves a site audit where we scope and inspect existing scaffold that is, or has been erected on a regular basis to access, protect or provide support in a mobile or fixed plant application. If applicable we design, engineer and construct a temporary or fixed solution to completely eliminate the need for scaffold.

The risks of scaffold

Bringing scaffold into a mining maintenance or inspection project carries a number of risks and extra ongoing costs.

- The requirement for extra non-company personnel on-site

- A minimum of 3 scaffolders needed on-site for a job to build and breakdown

- The hire of the scaffold

- Parts and personnel are not always available

- Scaffold must be regularly inspected and is often not

- Non-inspected Scaffolding often left in place due to lack of permanent platform to use a portable access solution

- Scaffold in not a form of permanent access or support

Australian and New Zealand standards require a licensed rigger to legally erect scaffold. The rigger is responsible for the assembly and installation of rigging gear such as ropes, pulleys and winches to lift and lower position equipment. The appeal of scaffold is often its temporary nature; however, scaffold is a system that is simply less secure with far less structural integrity. A single site may need numerous scaffold to be set up and taken down, requiring extensive time and man-power, reducing productivity and efficiency.

Scaffold incidents

Being temporary, scaffold lacks structural integrity and can become warn and damaged in its constant building and breakdown and not to mention extremely costly. Failing to monitor its condition and ensure its continued compliance can become dangerous. In November of 2015, a man working at an aluminium refinery in Western Australia died after falling from scaffold. There have also been several incidents where stair modules have failed. One incident involved several welds at the end of a module giving way when a worker stepped onto the landing, the worker’s hand was caught, resulting in the loss of a finger. Faulty welds, inadequate support and damaged stair modules have all been contributing factors to scaffold incidents and fatalities.

Scaffold elimination cost savings

We completed a cost analysis of one of our customers situations, before and after the use of our access platforms. Over a 1-year period scaffold was used 6 times at a cost of approximately $25,000 for each build and breakdown, this totalled over $150,000 for the year. Our solution was a single aluminium platform that required no skilled installation, no hire, less inspections and no extra personnel onsite for a once off cost of $30,000. This provided an immediate $90,000 saving; the platform has now been in use for over 5 years, creating an ongoing saving of over $450,000.

Certification and compliance

If you would like to learn more about the benefit certification and compliance can provide and how we can facilitate them for you, download our free whitepaper 10 Valuable Benefits Certification and Compliance Can Add to Your Site or get in contact with one of the team today and discuss you project or problem, we look forward to hearing from you!

About The Author: Rhys Werndly

More posts by Rhys Werndly