WA1200 Bucket Work Platform

The Komatsu WA1200 bucket and bucket arms often require servicing due to their constant workload. Welding, bushing, and changeover of bolts are common practices during bucket maintenance which requires a safe and robust working area for maintenance personnel.

A valued client of ours was dissatisfied with their current method of maintenance access, prompting them to get in contact with one of our team to come take a look.

A quick site visit to assess the situation was all that was required to develop a solution.

SOLUTION

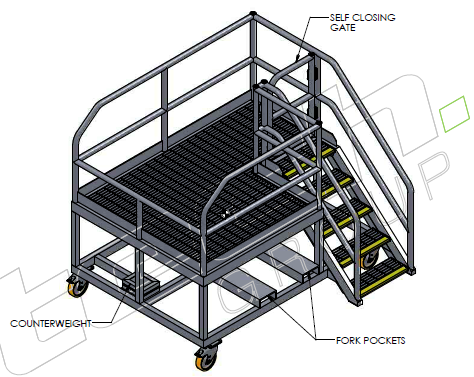

Our design and engineering team put forward the solution pictured to the left.

The bucket work platform is designed to provide safe access to the WA1200 bucket and arms for inspection and maintenance, while also providing a robust and efficient working area for maintenance personnel. It is sold in pairs with both platforms possessing built-in nylon brackets to line the point of contact with the bucket. This platform is specifically built for the WA1200 but can easily be modified to suit any brand of loader on request.

The platforms are constructed in heavy-duty but lightweight aluminium with high quality German made castor wheels to make it easy for anyone to move around. They are also built with jacking stands, a self-closing gate, and a non-slip stair way and work area to enhance protection.

RESULT

Our designed, engineered and fabricated access platform was delivered to site on time and on budget where it has been in use as seen in the picture above.

If you would like to learn more about our on-site consultation or our MEM access solutions get in contact today!