Materials need to be stored and organised safely on-site to reduce the potential of major incidents. Unsafe and uncertified storage can cause a number of significant risks. The common storage and racking problems include:

- No certification

- Poor configuration

- Lack of storage efficiency

- No steel storage racking at all, leaving materials and the equipment on the ground

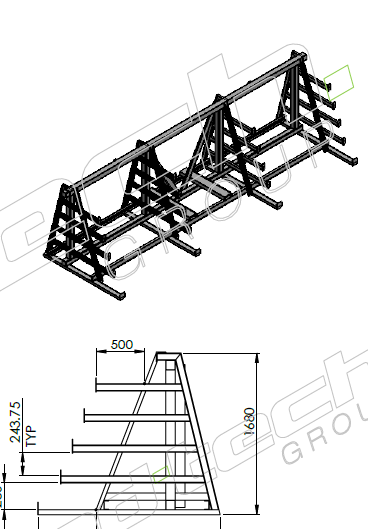

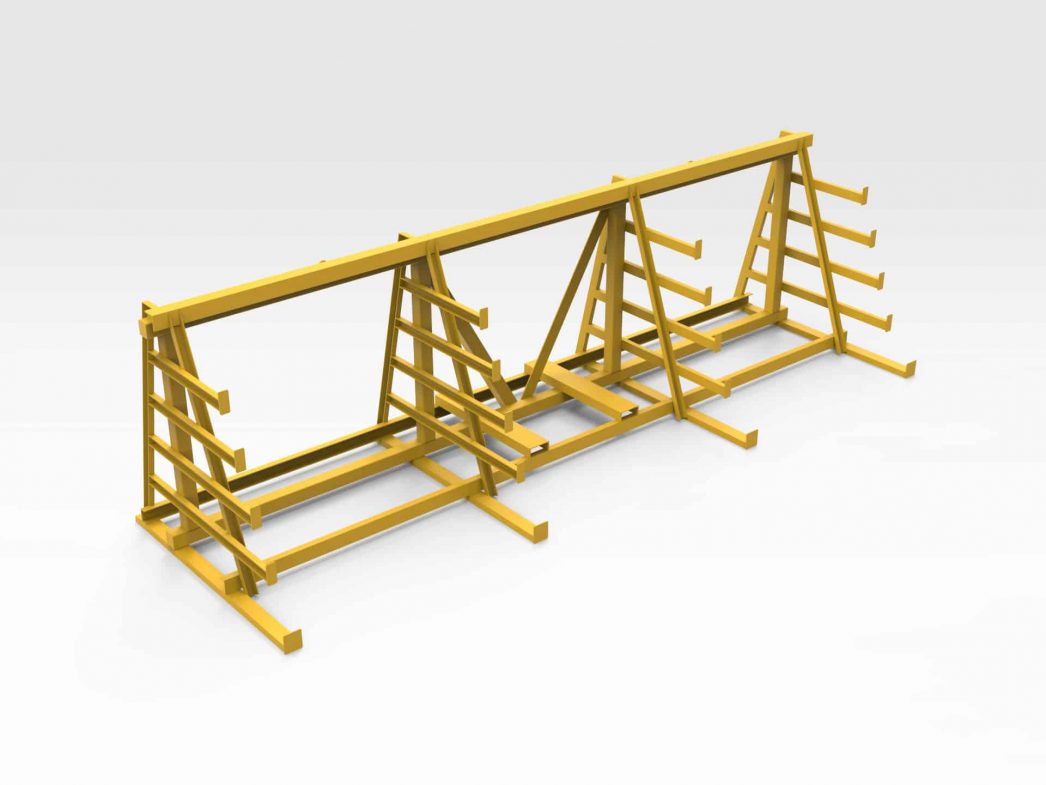

- Wrong rack for the materials being stored

These issues left unchecked could mean your current storage is significantly overloaded for its specifications, potentially placing operators and workers in the line-of-fire. These are incidents that occur as a result of falling, swinging or erecting objects, which according to SafeWork Australia, lead to 34 fatalities in 2019 alone. Unfortunately, it is still common to see unsafe and uncertified storage in the workplace.