Businesses that invest in better workplace safety measures mitigate the risks of workplace accidents which leads to improved profitability, staff morale and greater efficiency. Businesses also have a legal and ethical responsibility to provide a safe place of work for all employees and contractors on site.

For more than 30 years Bend-tech has been enhancing safety and efficiency in the workplace, delivering intelligent design and custom-certified products to the Mining, Defence, Fabrication, Marine and Oil and Gas industries across Australia and around the world. Our commitment to providing the highest quality products means our production is held to the highest possible standard.

What is a standard?

Standards are voluntary documents that outline specifications, procedures and guidelines. They are aimed at ensuring products, systems and services are reliable, safe and consistent. Standards are regularly audited and reviewed by the Standards Australia board to ensure they are applicable with current practice and are up to date with new technologies and advancements.

Standards and the law

Standards are, on their own, voluntary, however they are often referred to in legislation, when this occurs they come a mandatory benchmark of acceptability. Products that do not comply can be considered inferior as they have not passed the certification and testing required of an Australian Standard® compliant product.

Bend-tech’s Certification Process

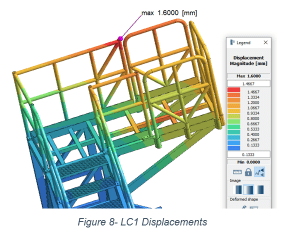

Stage 1: Preliminary analysis

The first stage of certification begins with our design and engineering team. Once we have received a custom engineering project from a client, a concept drawing is complete and put through FEA (finite element analysis) testing to assess load-bearing. Depending on what our client requires, we will choose the appropriate standards to test. Common Australian Standards® that are tested to exceed include:

AS4100 – Steel Structures

AS1170 – Structural Design Actions

AS1657 – Fixed Platforms, Walkways, Stairs and Ladders

AS1554 – Structural Steel Welding

AS1892 – Portable Ladders

AS1576 – Scaffolding

Stage 2: External report

For the large majority of projects, our engineering team will do a final review of the report and approve for certification. For some of our largest structural projects, the report will be sent to a third party for further testing and final approval.

Following approval, the concept is then submitted to our client in a structured report which is formatted to their specific requirements. If there are any changes required, we will make the adjustments and the revised concept will be put through the necessary tests and re-submitted to our client. This process is repeated until the concept is approved and the final draft is submitted.

Stage 3: Certification and fabrication

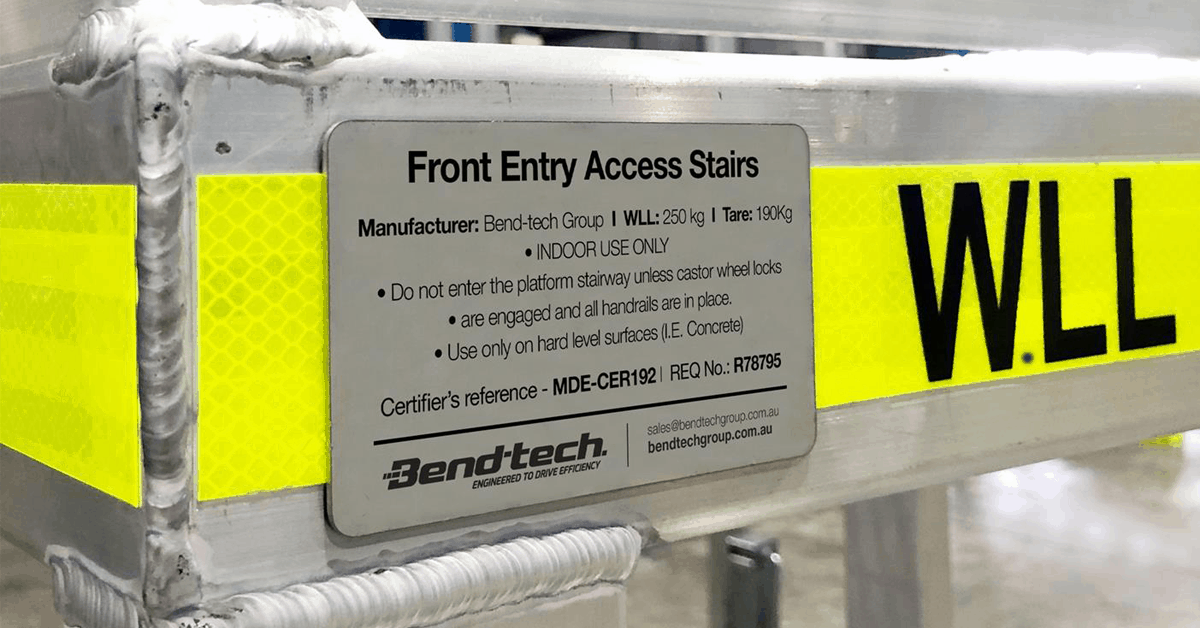

To finalise the certification process, an engineering certificate and certification plate for the design will be confirmed. The plate is usually engraved with the Australian Standards that are met and the certified weight load limit.

Once the design is fully certified and approved by our client, our production team in Western Australia can commence fabrication.

Conducting this extensive certification process may add some time onto the project, but it ensures every product that leaves Bend-tech is designed, engineered and constructed to the highest of standards. If you would like more information about the benefits of certification, download our free whitepaper or get in contact with the team today!

About The Author: Jake Marinovich

More posts by Jake Marinovich