Cone Crusher Platform and Stand

Primary crushers play an integral role in the mining process by reducing the size of large run-of-mine ore pieces to acceptable sizes.

The main shaft is a large cone-like structure which rotates within a chamber, crushing the large rocks which are being fed

into the system by haul trucks.

As the system is operational 24/7, the main shaft incurs extensive damage requiring routine maintenance in order to maintain

consistent operation. Current maintenance methods involve using scaffolding to access damaged areas which can be an

unsafe and inefficient process. Read our Benefits of Eliminating Scaffold blog for more information.

A valued client consulted Bend-tech about engineering a safe and efficient access solution for cone crusher maintenance.

SOLUTION

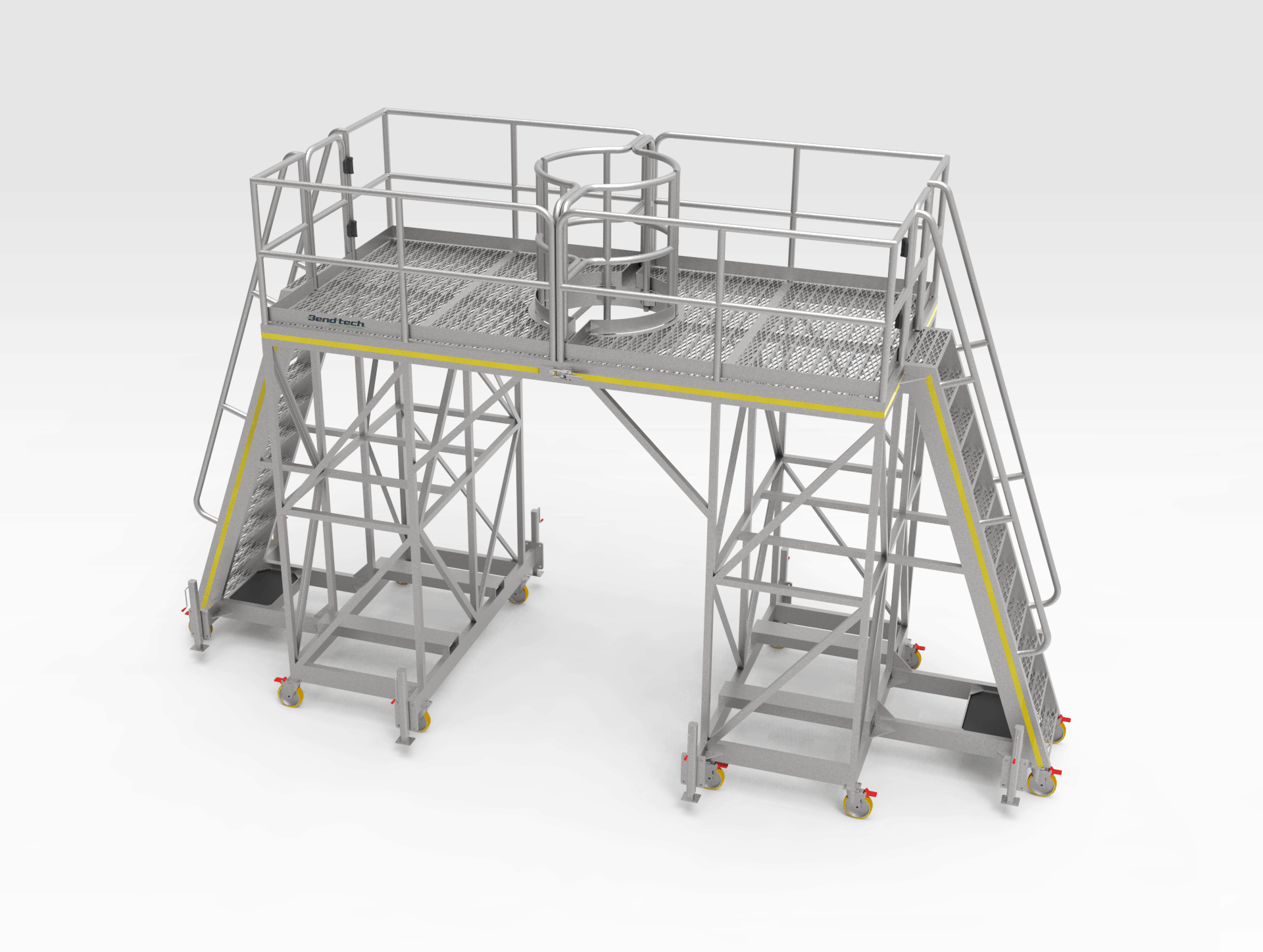

Our engineering team drew upon their knowledge and experience gained through similar projects to design a safer access solution which eliminates the need for scaffold.

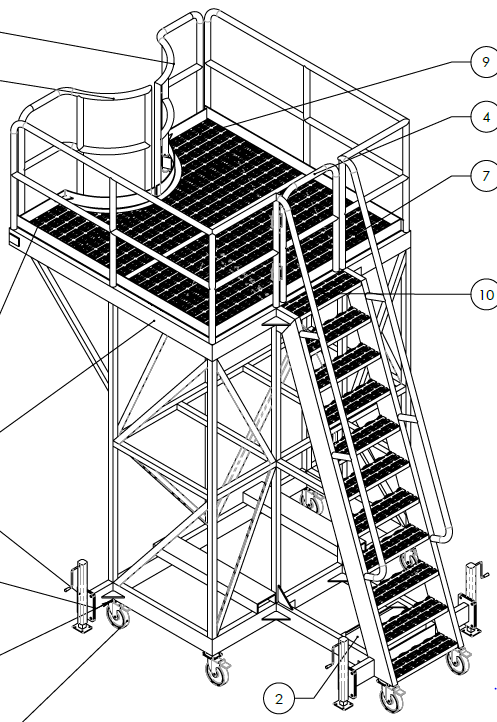

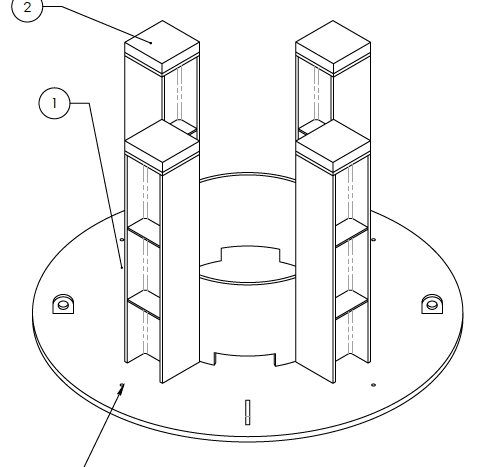

The design (pictured below) incorporates a stand to ensure the main shaft is secured when it is lifted out of the crusher for maintenance. Two access platforms (pictured left) are designed to join together around the shaft creating a large area where multiple maintenance personnel can work on the damaged areas.

Each platform is fitted with heavy-duty lockable Richmond wheels and levelling jacks ensuring a safe and stable platform base. The

platform is also equipped with a self-closing gate and yellow non-slip safety nosing fitted to treads to ensure maximum safety

during maintenance.

Although this is a fixed platform which can be stationed in an area best suited for maintenance, it can also easily be transported

and stored via the forklift slots which are fitted on the platforms and the stand.

RESULT

Our cone crusher platform was constructed and delivered to site on-time and on-budget. More sites throughout Australia are opting to eliminate scaffold and use our specifically designed, engineered and certified access platforms which provide greater safety and efficiency during maintenance.

See more of our case studies for a better understanding of how Bend-tech maximises on-site safety and efficiency.