Truck Strut Oil Module Service Unit

A valued client got in contact with one of our consultants about some issues they were having with the oil transfer and filling of their Caterpillar Mine Truck struts.

Their solution, pictured to the right, was to use a 44 gallon drum with air operated pumps that required many unnecessary hoses and components.

This solution was uncertified, untested, and ultimately created potential hazardous scenarios, and damage to their efficiency.

The client wanted us to develop a solution that solved these issues and was self-contained. The client also requested that the solution could drain two struts at the same time while also providing the ability to refill two struts at a time with new oil.

SOLUTION

The project was put to the design team and we went to site to gain further insight into exactly what was required. In collaboration with the client, we developed some concepts for approval.

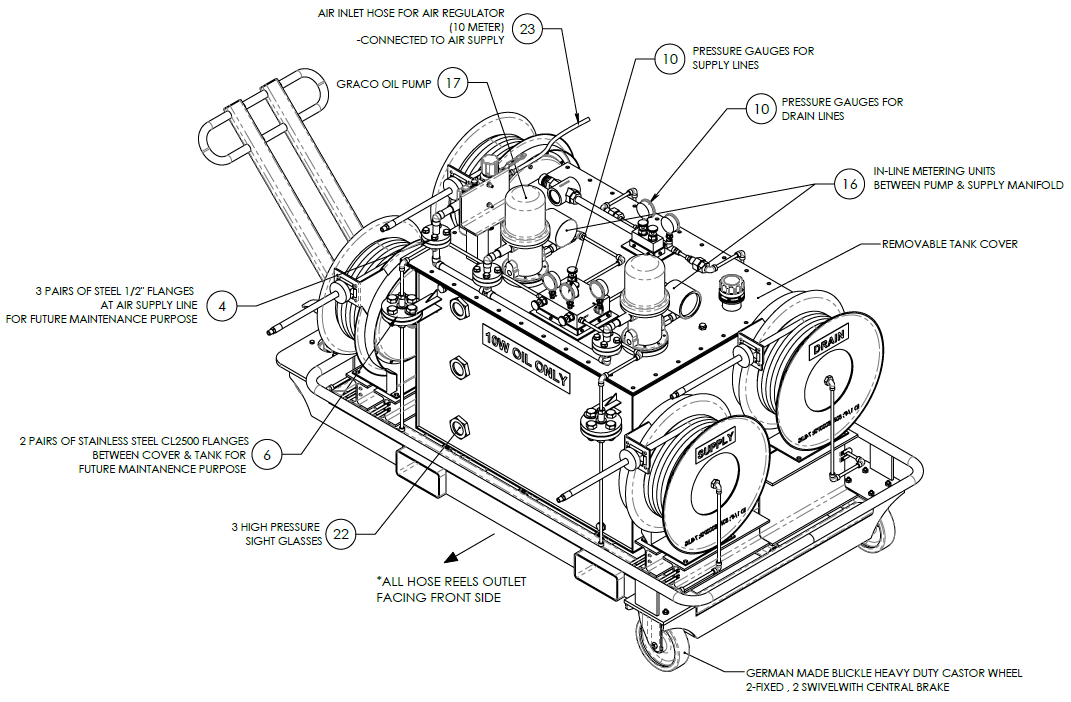

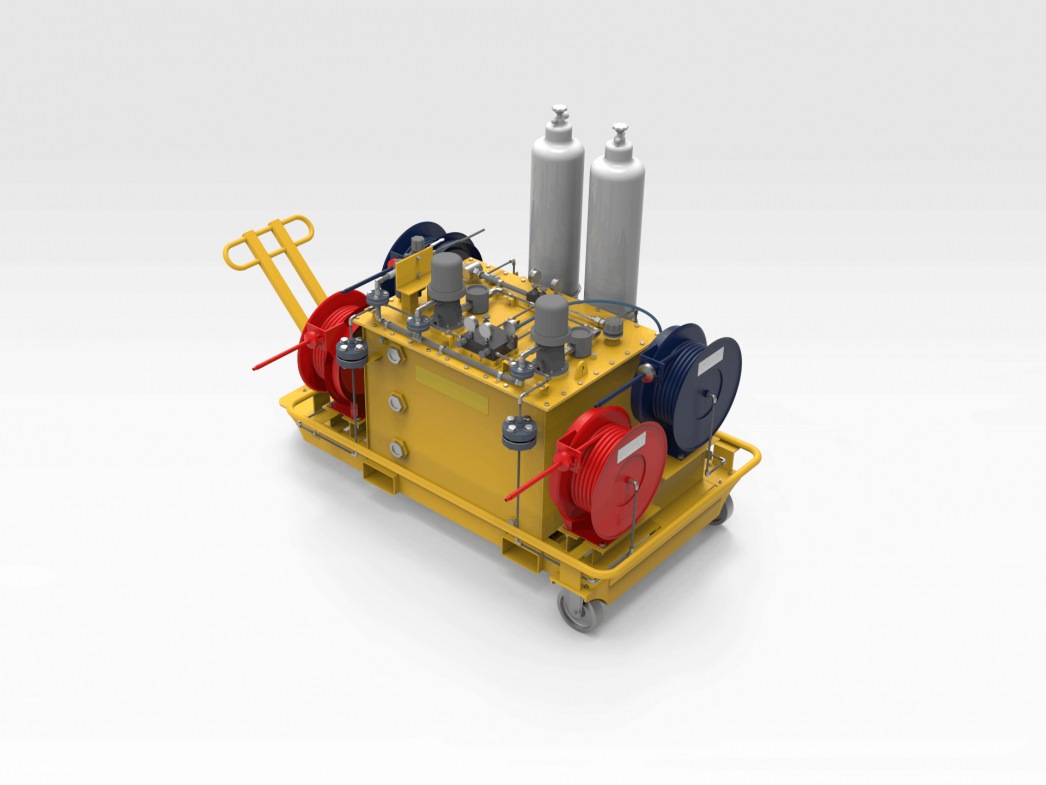

The final solution involved constructing a 400 litre oil tank fitting two air operated pumps fit with pressure gauges, two drain hoses which are hitched up to struts to drain the old oil out, as well as two filler hoses to fill the struts back up with fresh oil.

A nitrogen filler bottle storage and mount system and tank viewpoints to check oil levels were also included to enhance safety and efficiency.

The oil module is complete with certification, giving the client peace of mind by ensuring it is safe and free from hazards.

RESULT

After the careful design and engineering process, the oil module was complete and delivered to site. The unit has since created a real boost and efficiency on-site, making a previously painful part of maintenance much easier.

We are excited in being able to provide multiple of these units and give the people on site the equipment they need to be as safe and efficient as possible.

Watch Kelvin explain how the truck strut oil module service unit works in more detail in our video to the right.