Rail Axle Stands

Locomotive rail axles constantly need to be replaced, requiring rail service areas to hold a large stock of new and repairable axles.

Current storage solutions for these large, cylinder shaped axles are generally messy and unsafe, such as the use of wooden crates or no storage solution at all. Unsafe storage of axles can potentially lead to trips, falls, or the heavy axle rolling dangerously into work areas.

SOLUTION

A valued client made an enquiry with our engineering team about the design and fabrication of a safe and certified storage solution for the axles.

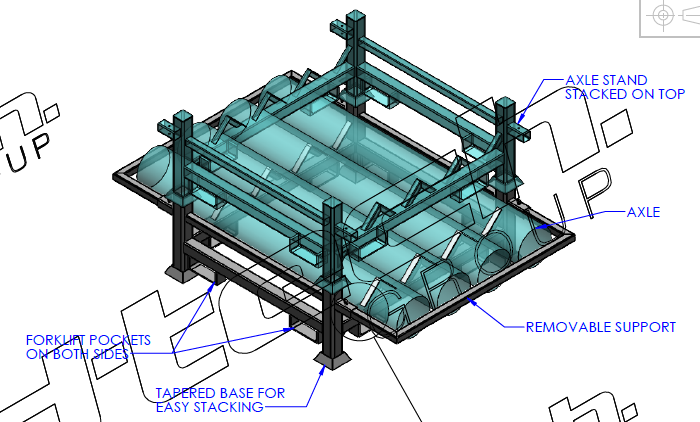

After a short back and forth design process, the proposed solution pictured to the left was put forward.

The rail axle stand is made of a heavy-duty steel construction which can safely hold 4 axles per frame. Each frame is designed to be stackable up to 4 times, meaning 16 axles can be stored safely in the confined area.

Each stand is certified to a 2.8 tonne weight load limit and is fitted with forklift slots for ease of movement. Axle holders are also fitted with rubber plates.

RESULT

The rail axle stands were fabricated and sent to our valued client based in the Pilbara. We have received positive feedback regarding

the increased safety and efficiency provided by the storage solution.

Bend-tech has provided designed and engineered storage and access solutions for various sites throughout Western Australia,

see our case studies page for more.