Primary Crusher Work Platform Project

Shut down teams on-site in the Pilbara were working on their Primary Crusher with poor cover from the elements.

The area was also restricted given the amount of tooling, airlines, power cords and gas lines running through the work area. This was presenting slip, trip and fall hazards. Access to welders, power generators and air compressors was also restricted as these units had to be positioned on levels below work area or on the ground.

This previous set up also required temporary lighting and ventilation systems to be brought in and set up every shutdown, impacting maintenance efficiency.

SOLUTION

The site got in contact with one of our consultants during a shutdown to discuss their problem. We went to site and viewed their photos and current working environment, although standards across the mine site needed some attention.

We scoped the area and its associated problems and consulted with maintenance personnel, crane operators, supervisors and superintendents to come up with a suitable solution to eliminate their issues.

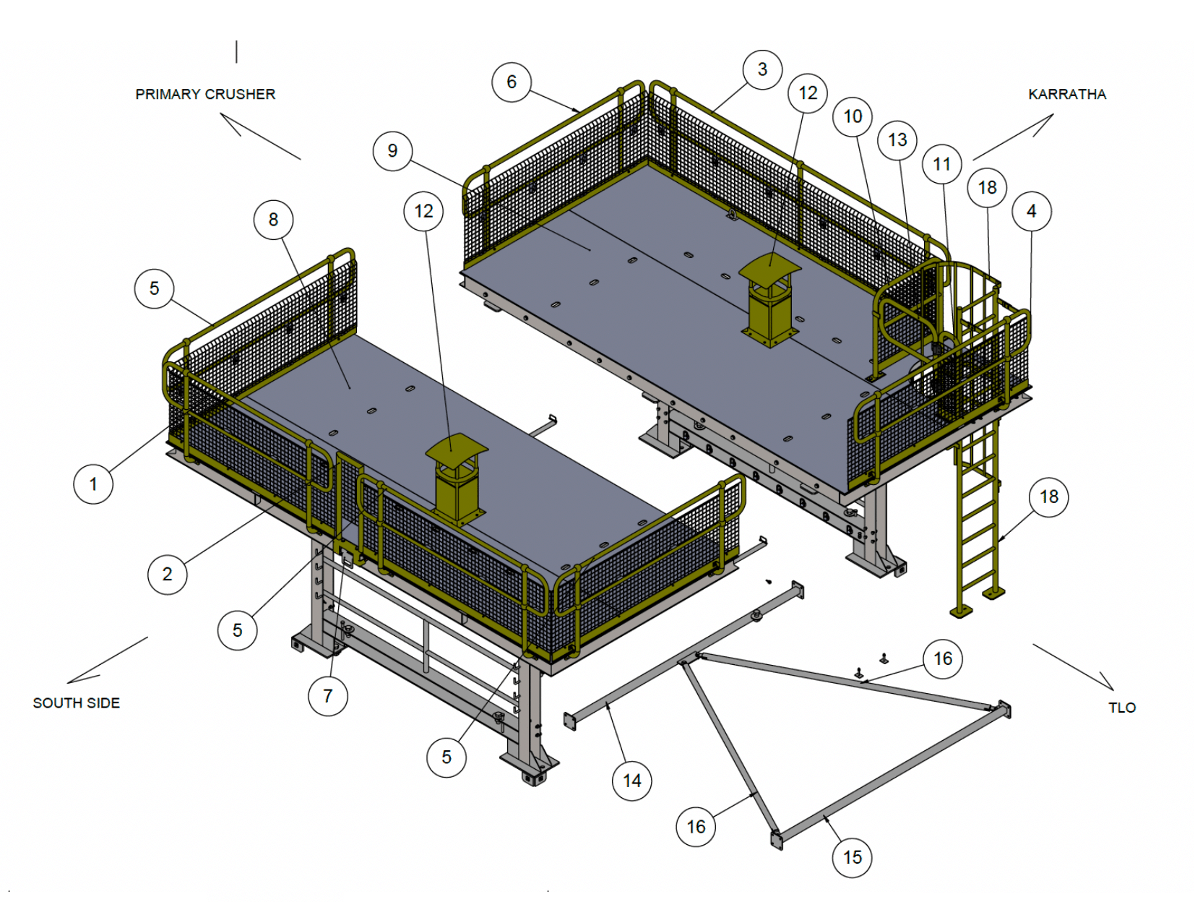

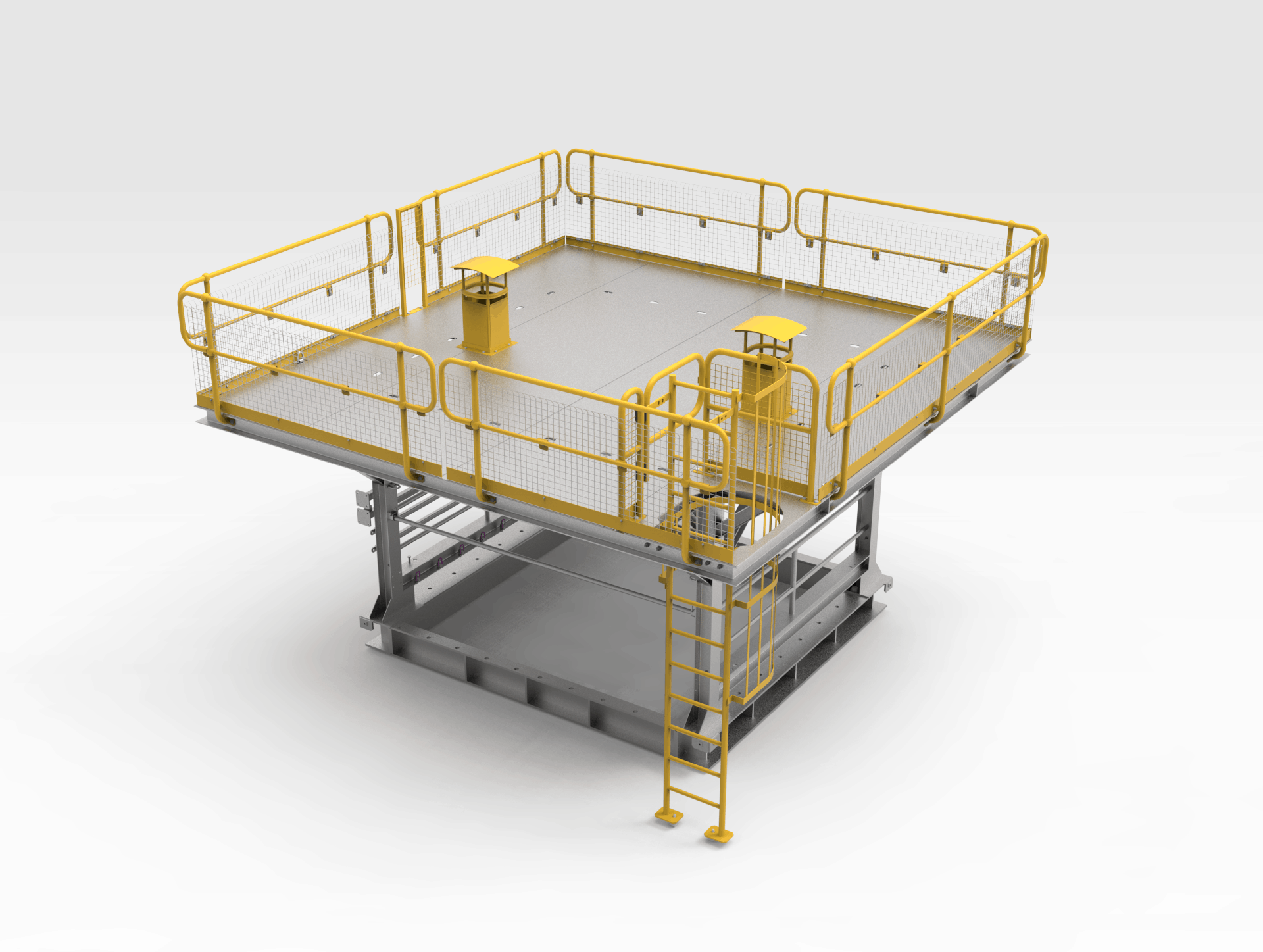

Our solution was the platform and work cover pictured to the left.

This platform acts as a cover from the environmental factors such as sun, win and rain as well falling dust and debris.

The roof section while acting as a cover is also a load rated work platform which all welders, air compressors and gas bottles can be stored on. All extension leads and lines are then run through the two specified hatches (12) in the platform floor to bring the necessary power and gas directly to the teams.

The platform sits on the existing crusher structure and provides a safe and demarcated handrail surround. Site personnel can hang their caddy welders from the underside of the platform whilst built in lights and fans provide extra worker comfort.

The platform can be loaded up from the ground with all required tooling and lifted into place by one crane rather than the 5-6 require previously. The work area is cleared considerably from tooling and slip, trips fall hazards whilst providing greater worker comfort

RESULT

The platform was delivered to site complete with assembly and installation manual. Maintenance on the primary crusher is now safe, efficient and easy.

Personnel working on the area of the plant are protected from the elements and have immediate access to tooling and ancillary equipment required to complete maintenance and associated shutdown works.