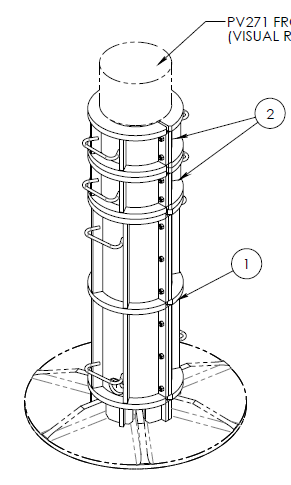

PIT VIPER 271 JACK STAND CLAMPS

Drills such as the Epiroc Pit Viper 271 are found on every open-cut mine site for rock blasting. Although many drills in Australia are now autonomous, physical interaction

is still necessary for routine inspection and maintenance.

These drills are equipped with one or multiple hydraulic jack leg stands which keep the drill level and stable during operation and down time. In general, these stands

have a very low chance of failure, but if a stand were to fail during maintenance, serious injury or death would almost be certain.

SOLUTION

This issue was raised some time ago by a valued client out at a site in the Pilbara. Safety standards in mining are among the highest of any industry in Australia, so although there is a very low risk of failure in this case, there have been calls to eliminate it altogether.

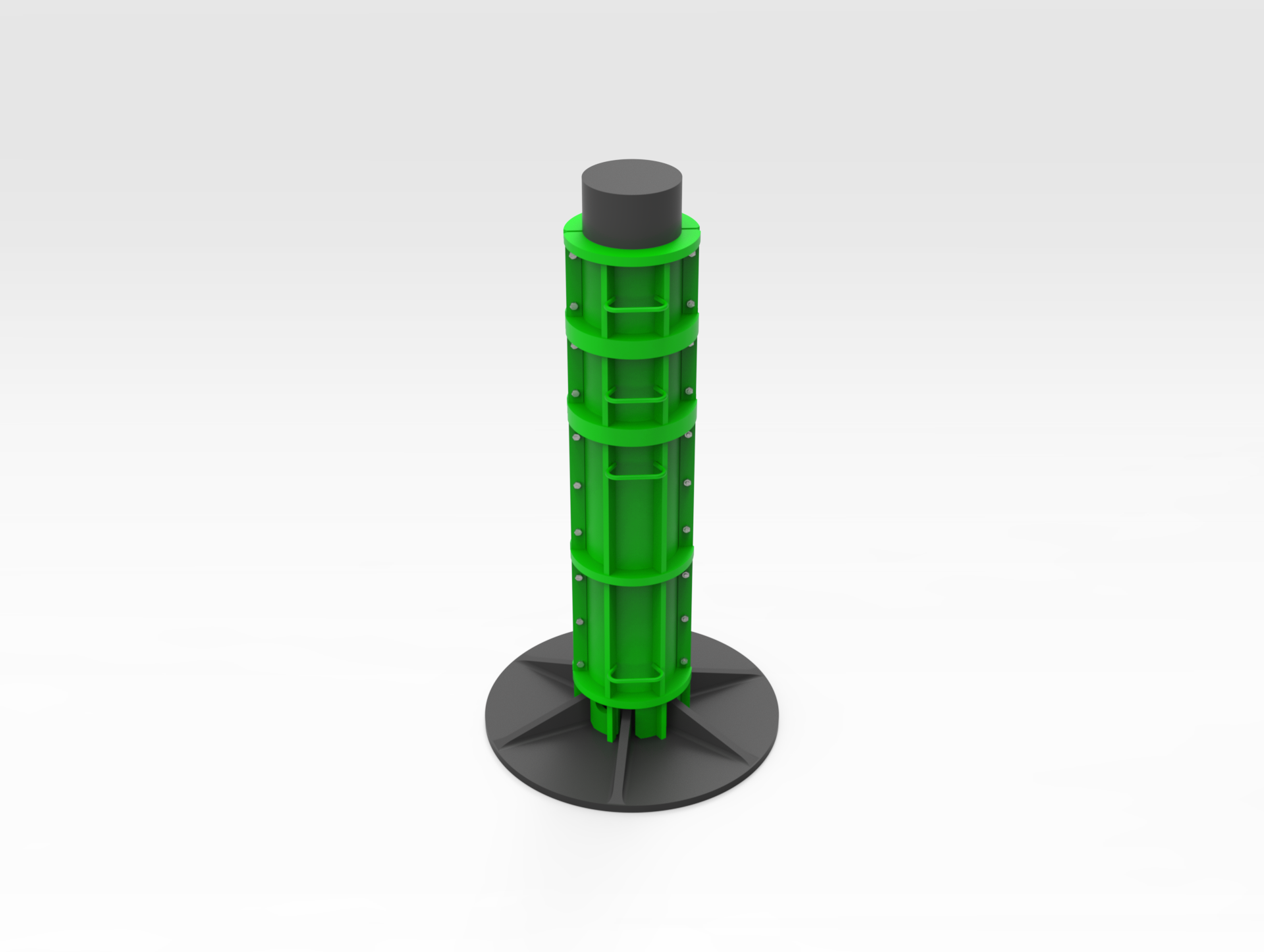

This was put to our design and engineering team who used their knowledge and experience from similar projects to put forward the solution pictured to the left.

The Pit Viper 271 Jack Stand Clamps are constructed in heavy-duty but lightweight aluminium. They come in two halves to make handling and instalment easier and more inclusive, which connect together around the jack leg stand providing a fail safe lockout if the hydraulic system were to fail.

The clamps are certified, rated and engineered to Australian Standards.

RESULT

Our goal is to make maintenance on-site safer, easier and more efficient, with products such as these which take away that final percentage of risk.

Our jack stand clamp range is continuing to expand across the Epiroc drill range and into other brands. Be sure to get in touch with our above ground parts specialist Damon McEwen for more information.