Pilbara Rail Project

Operators from a locomotive service workshop were experiencing difficulties when trying to access certain areas requiring maintenance on the locomotives.

The current handrailing set-up was fixed and would often get in the operators way, as you can see to the right, causing inefficient maintenance. The handrails were also unsteady which could prove to be a safety risk.

A valued client got in contact with a Bend-tech consultant about redesigning their handrailing set-up with the aim to provide safer and more efficient access to locomotive maintenance.

SOLUTION

Our consultant went to site to gain further insight into the landscape and operational set-up. The project was then put to the design team

to work out the safest and most efficient handrailing solution.

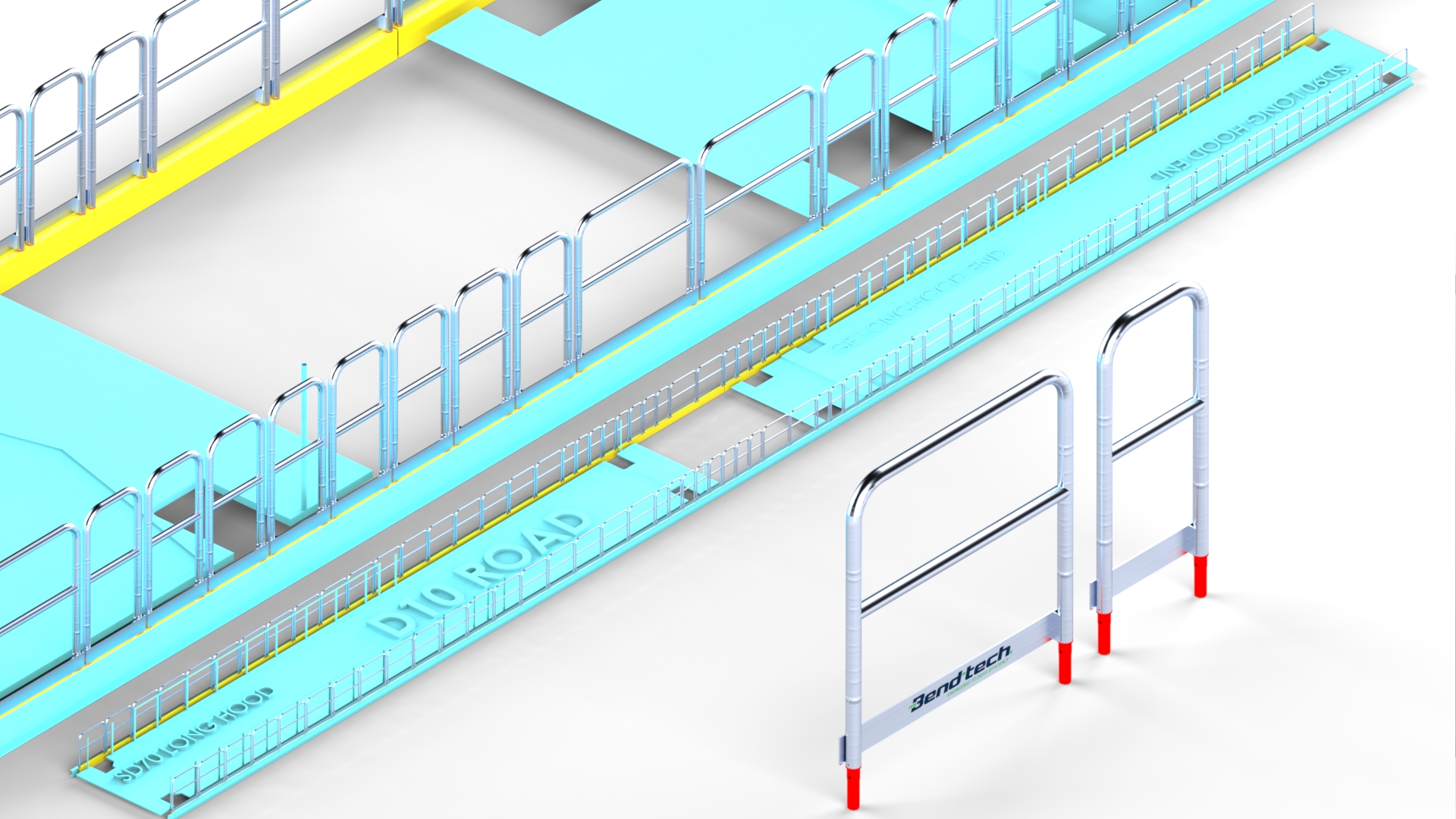

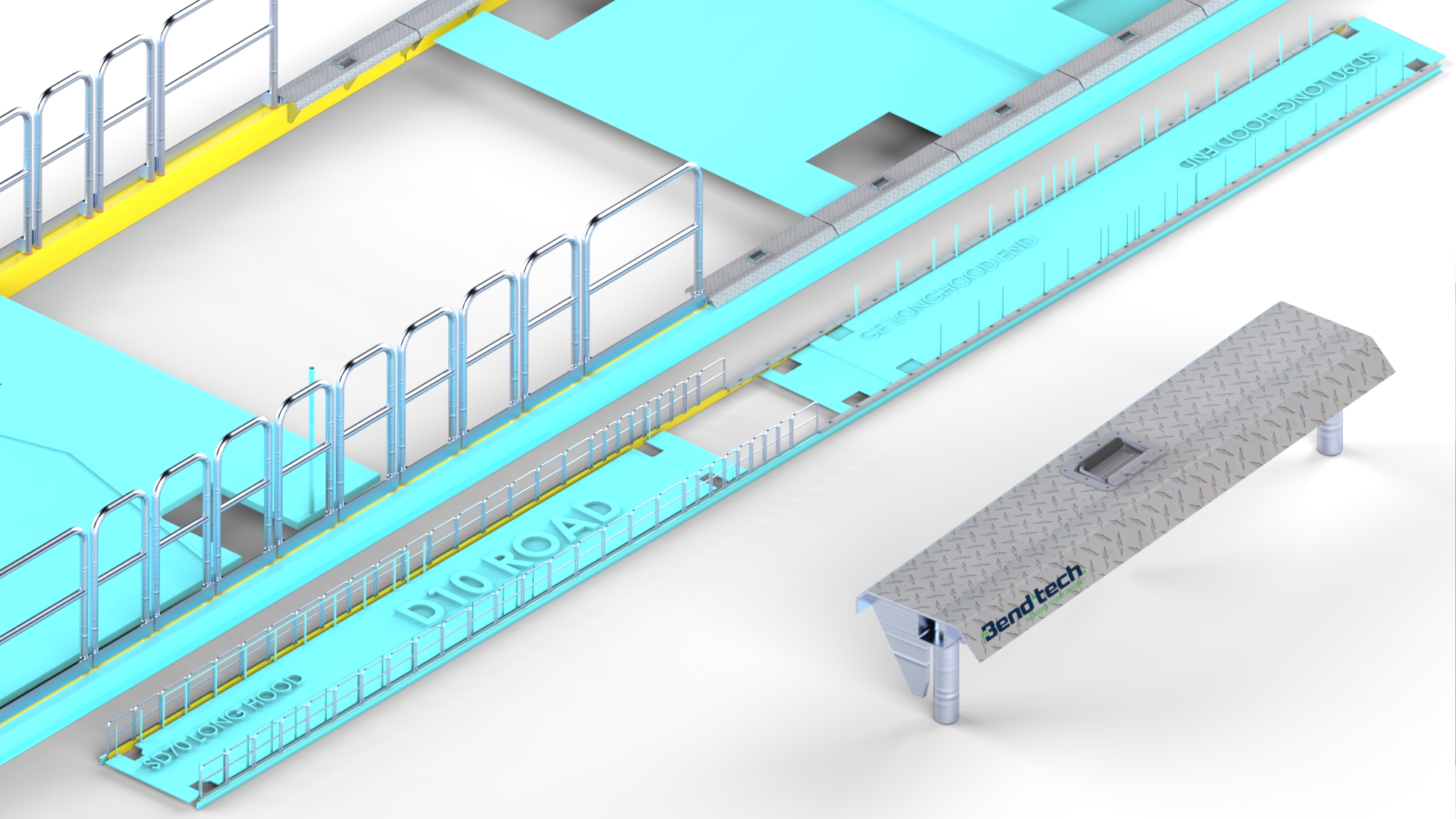

The design incorporated a series of individual handrails lined up along the edge of the working platform which are all removable. The

handrails are made of heavy-duty steel and are engineered to the relevant Australian Standards. We went one step further in the

design ensuring that the main areas of each of the four types of locomotives that required maintenance would line up perfectly

with the handrail set-up.

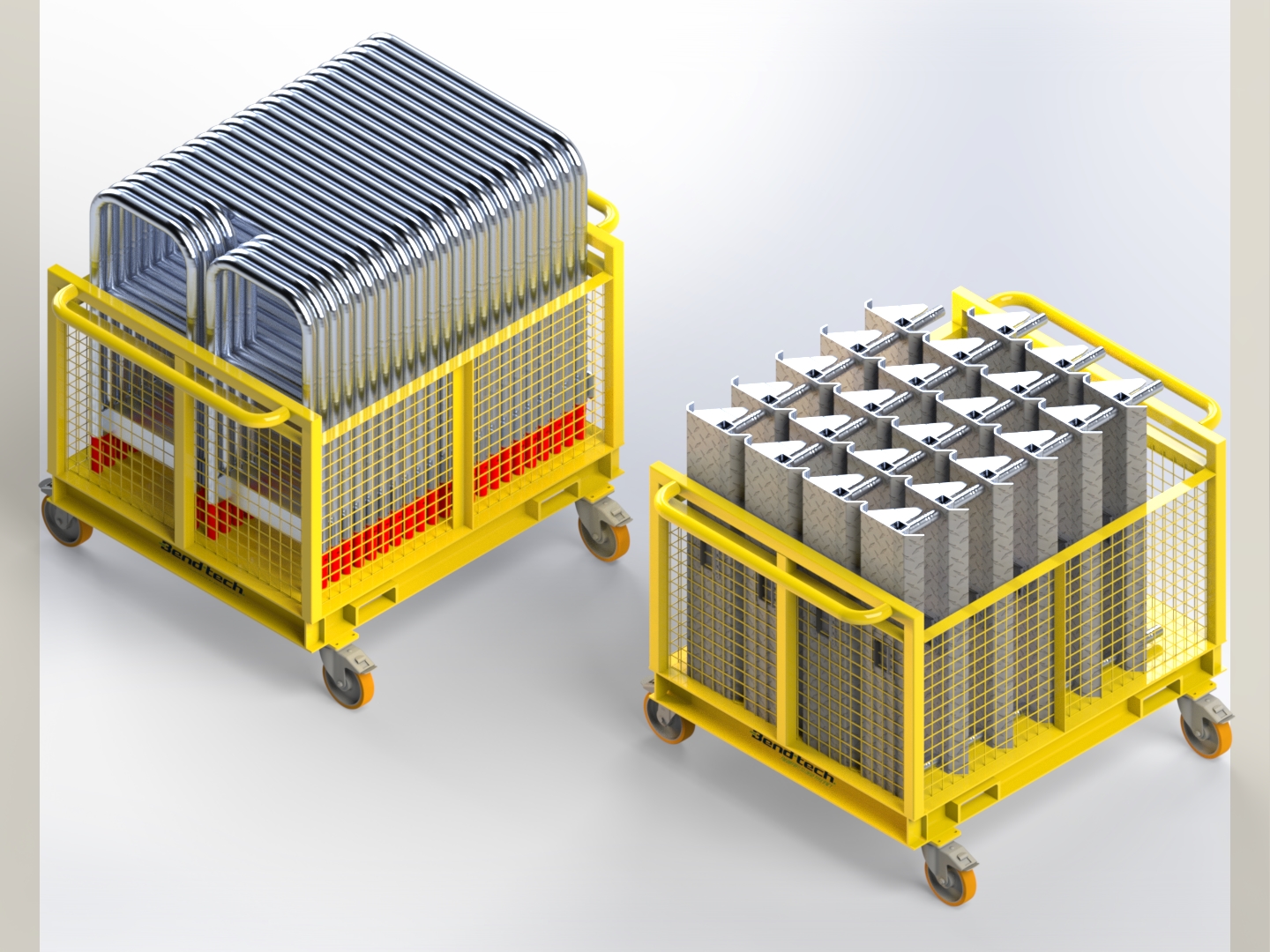

For enhanced safety when handrails are removed, they are replaced with blocks which cover the gap between the platform and

locomotive. For increased efficiency, storage trolleys/racks were designed specifically for the handrails and the blocks.

RESULT

This solution went through many phases of consultancy, design, engineering and construction to ensure the best possible result was achieved.

The strategically placed removable handrails will enhance the efficiency of operators during maintenance. The blocks are an easy solution to mitigating fall risks with the small gap present between the platform and locomotive. Both items together with their specifically designed trolleys have made maintenance safer and much more efficient.

Bend-tech has the capability to undertake unique projects such as this and provide a complete designed and engineered solution to enhance your maintenance safety and efficiency.