MT65 Mid Access Platform

A maintenance specialist out of BHP’s Olympic Dam Mine got in contact with one of our consultants about providing a safer access solution to the mid-section of the MT65 underground mine truck.

The current access method (step ladder) presents a significant fall risk as the operator has to lean over the edge to reach certain areas. The areas that need maintenance are up to 3 metres high meaning a fall has the potential to cause serious injury or worse.

SOLUTION

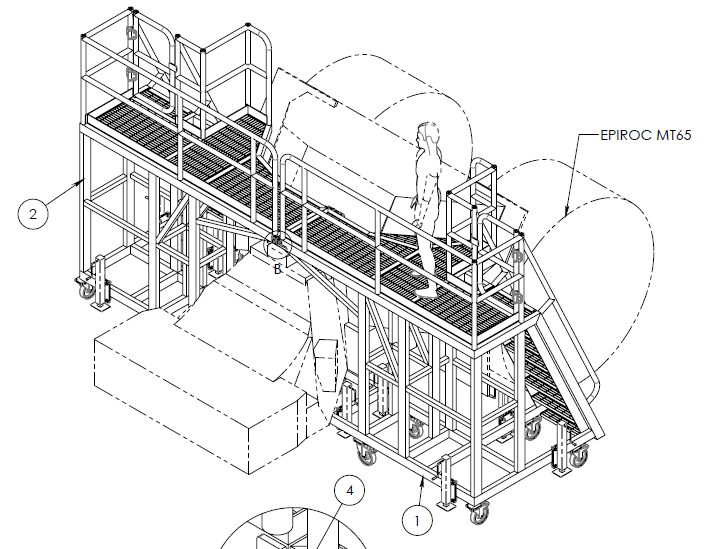

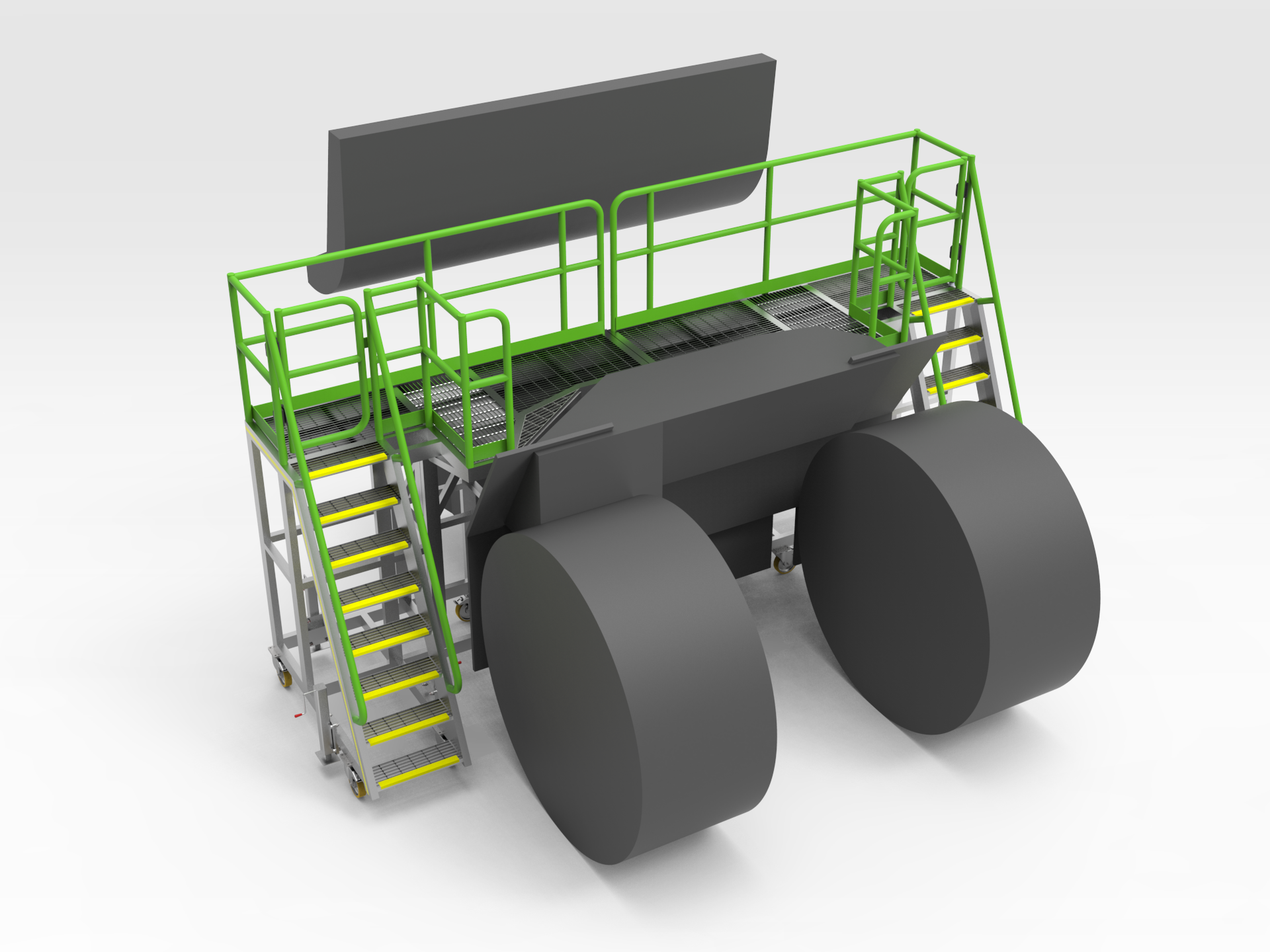

The enquiry was passed on to our design and engineering team to provide a safer access solution. Using the knowledge and experience from similar projects, the team came up with a solution pictured to the left.

The team designed two parallel platforms to fit around each side of the mid-section and link up in the middle. The design allows maintenance personnel access to all necessary areas without the need to lean over the edge or reach up or down.

High quality German lockable caster wheels allow for ease of movement and storage. Also fitted are heavy-duty jacking stands to hold the platform safely in place during maintenance.

RESULT

The access platform was delivered to site on-time and on-budget. The MT65 mid access platform has since been implemented at a number of other sites across Western Australia.

Maintenance personnel can work with greater peace of mind knowing that their safety and efficiency is enhanced while using the mid access platform.