MINE SITE MAINTENANCE

Preventative maintenance provides tangible, long-term benefits to an organisation’s assets. Ensuring the plant, operating equipment and ancillary components are maintained, creates extended value, reduced costs, increased safety and boosts productivity.

Reacting to rather than preventing inevitable maintenance breakdowns inhibits an operations ability to conduct uninterrupted production.

Benefits of preventative maintenance

- Lower Your Maintenance Costs

- Improve Useful Equipment Life

- Increased Productivity

- Increase Residual Values

- Enhance Facility Safety

The way we partner with operations, offering an end-to-end solution development process means we are the solution to your maintenance woes. We can design, engineer, certify and fabricate or replace an existing piece of plant.

Our ability to access and work off your drawings or come to site, scope, scan and develop our own allows us to take the problem off your hands and deliver what you need to facilitate constant production.

Our solution development process

Projects and the associated challenges often require custom solutions, we take pride in our CDEC system. Consultation, Design, Engineering and Construction is our holistic approach to solution development making maintenance on-site safe, efficient and easy.

CDEC

Consultation

We come to you and visit your site to get a hands-on feel for your project. The aim of our consultation is to listen to and understand your requirements. If the project requires it, our 3D scanning capabilities will streamline measurement and data capture. This approach allows us to develop and discuss with you on-site, possible solutions to your problem, and the benefits we can offer.

Design

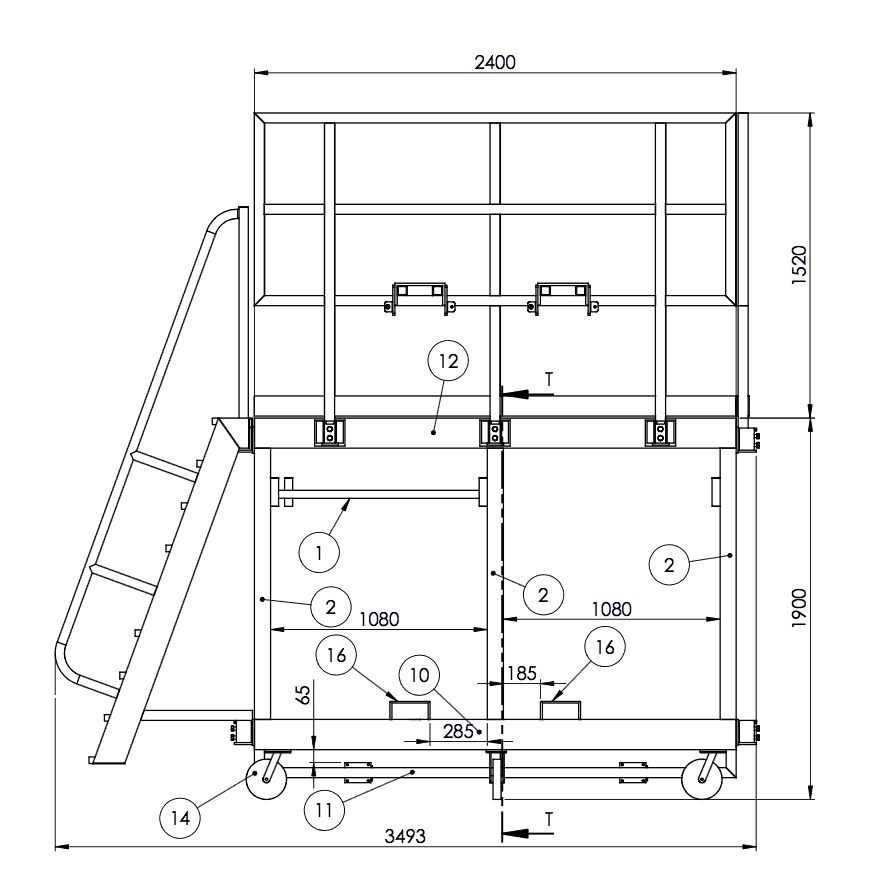

After the consultation we go back to our design team to begin the development of your custom solution. Our team produce designs in CAD Design complete with all drafting documentation ensuring an advanced manufacturing process. Our process allows and encourages you to be involved in the design stage and collaborate with our highly skilled team.

Engineering

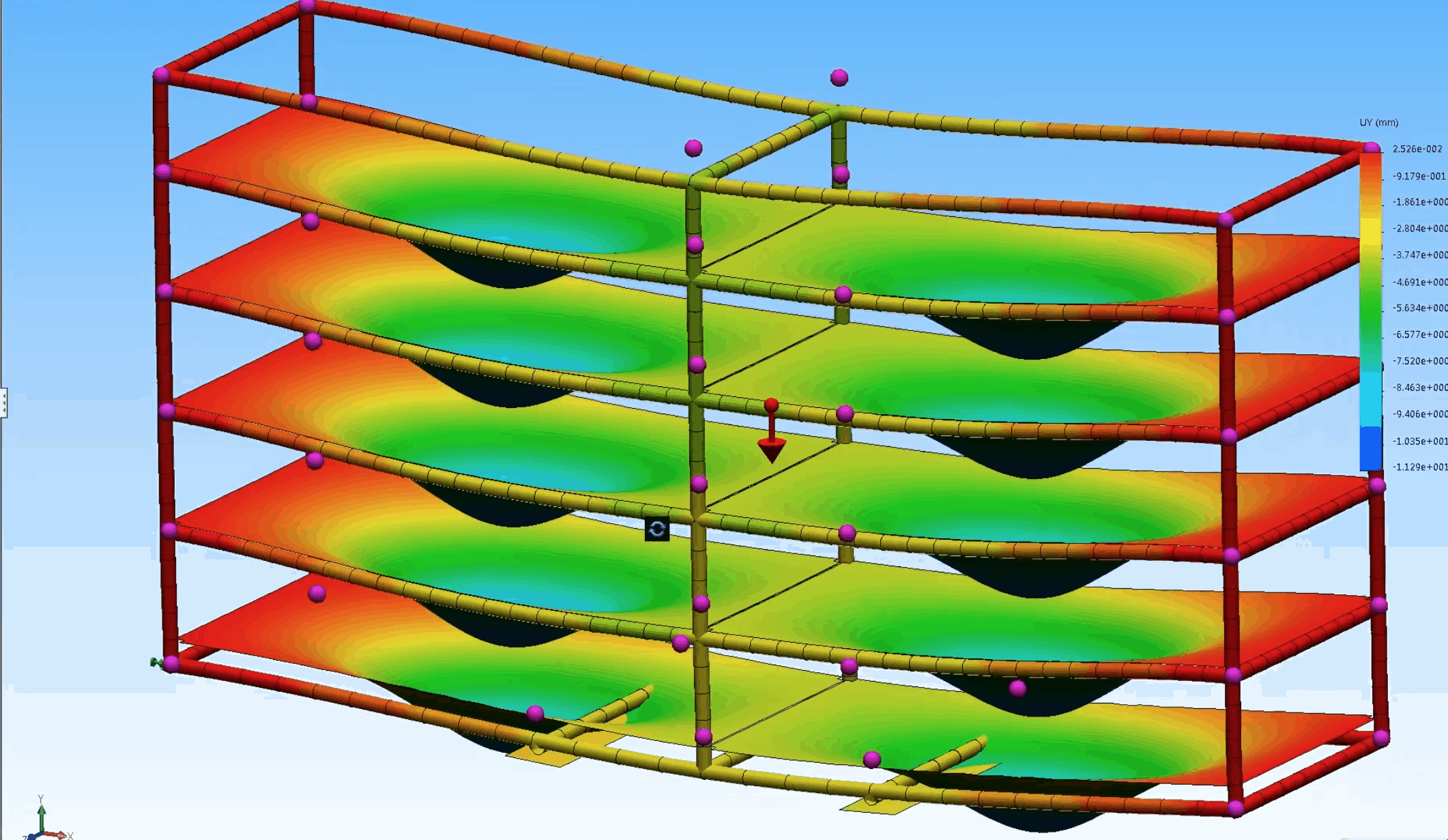

Once the design is approved, we begin the development and engineering process. This ensures that the right material is used for your project to guarantee structural and functional integrity. We provide full certification that includes WLL, load ratings, integrity reports as well as certificate plates and identifications. We design and engineer all our solutions to ensure full compliance with Australian standards.

Construction

Finally, once the project is ready and certified for construction, we manufacture your solution. We test, machine, fabricate and surface treat as well as trial fi t your custom project. We only manufacture high quality products that provide long lasting, safe and efficient solutions.

What our method provides the client

Our approach means your problems are in the hands of those that solve them.

Comfort

We take ownership of our role in operational efficiency with a system that provides a holistic solution.

Certainty

Being available, mobile and equipped to provide on-site consultations and scanning to ensure drawings, scopes of works and solutions are correct is invaluable.

Control

Design and engineering capabilities are crucial to providing certified and compliant solutions. We enable control over the situation.

Motion

Enabling processes and production to continue on-time is a crucial. We provide reliable, consistent pathways towards this goal.

Impact

Solutions that are executed on-time consistently leaves an impact on the bottom line. Productivity receives a boost which is compounded by the benefits of the efficient use of resources which are freed up due to efficient solution development.