L2350 Ball Cap Access Platform Case Study

Maintenance personnel are faced with significant risks when working on large mobile equipment on-site. The severity of these risks is enhanced when conducting maintenance toward the top areas of mobile equipment.

This is particularly relevant for accessing the high ball cap on the LeTourneau L2350 Wheel Loader, located 4 metres high on the side of the vehicle. Ball caps tend to require a forceful pull to take them out for repair or replacement.

The previous solution required maintenance personnel to reach above them and pull or try to remove the cap whilst holding on to the ladder. As seen to the right, there is very little room for movement on the narrow step ladder, increasing the risk of falling if the cap requires a forceful pull.

SOLUTION

A maintenance technician from WA’s Pilbara region made an enquiry about what Bend-tech could do to help make this action safer and more efficient.

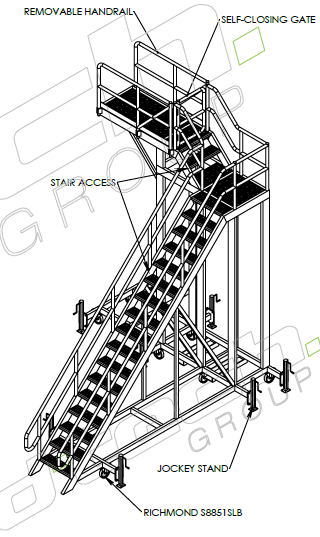

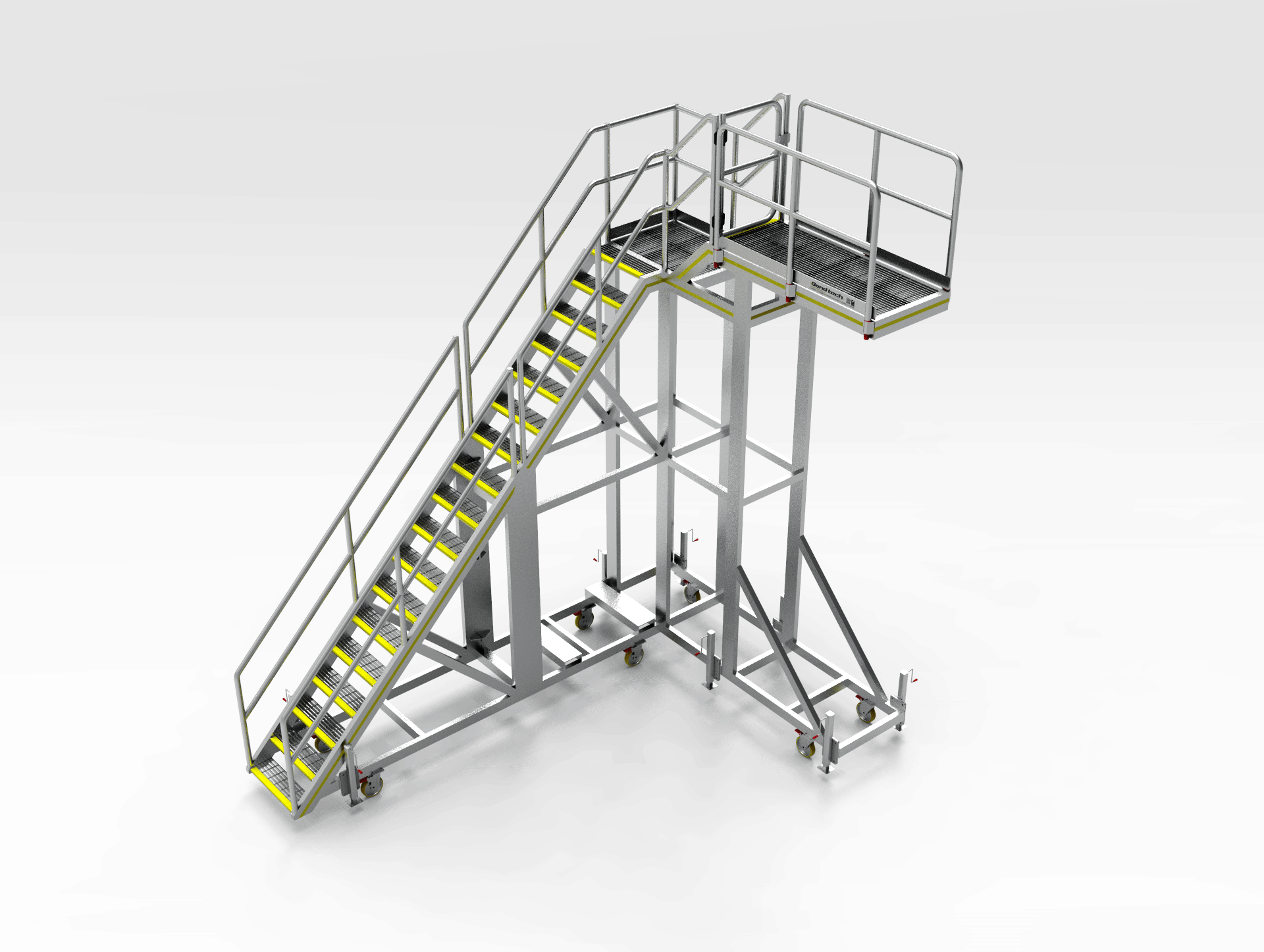

Our design and engineering team used their vast knowledge and experience gained from previous projects to come up with an access solution pictured to the left.

The design allows maintenance personnel a safer and more spacious working space through the large non-slip serrated stairway and work area and self-closing gate.

Bend-tech’s access platforms also come with high quality German lockable caster wheels and heavy-duty jacking stands as standard to increase movement and storage efficiency.

RESULT

The access platform was fabricated and delivered to site on-time and on-budget. Maintenance personnel were satisfied with the solution and can continue to work with greater peace of mind knowing that their safety is enhanced.

The L2350 ball cap platform is becoming a popular maintenance solution among sites in Western Australia’s Pilbara region. See our range of MEM platforms that have been designed and engineered to solve specific maintenance safety issues.