Electrical Cable Storage Rack

Cable wiring is used throughout mining operations particularly in fixed plant and underground settings. Cables range in size and

weight, with the larger cables weighing 80kg plus. This poses an injury risk for labourers manually lifting and handling the

heavier cables.

Another issue to consider is the storage method of cables, with many sites opting to use wooden crates spread out over a large

area, as seen in the images below. This is an inefficient and potentially unsafe practice which is why a valued client got in

contact with one of our Bend-tech consultants.

SOLUTION

The goal was to design a storage solution which will eliminate the need for manual labour as well as keeping the cables in a tidy and organised manor.

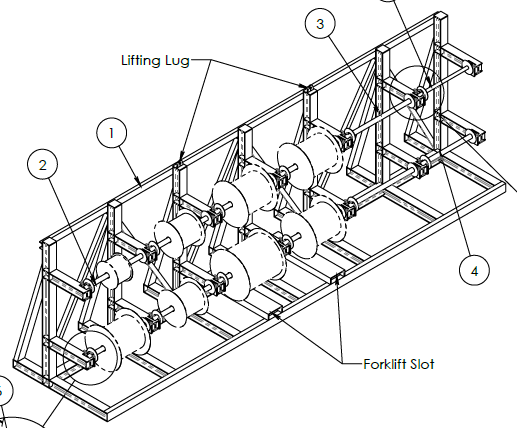

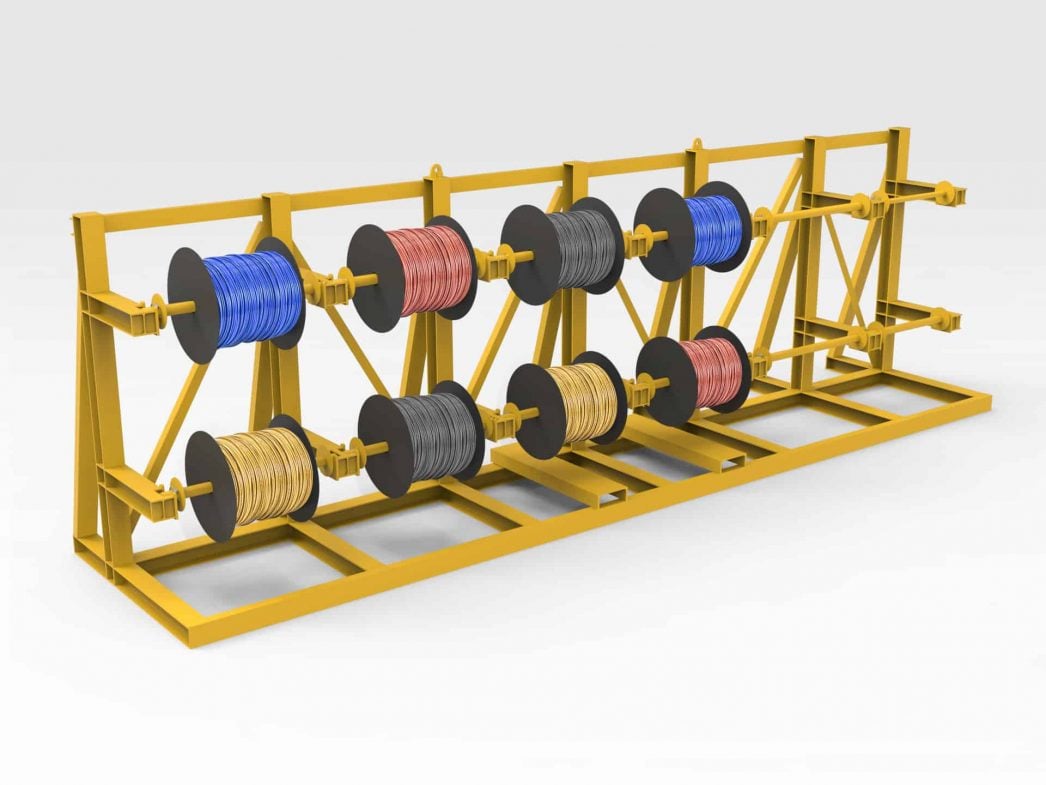

After a thoughtful design process, our engineers came up with the cable rack storage solution pictured to the left.

The cable rack is designed with 12 segments. 6 on the top horizontal bar with a weight load limit (WLL) of 300kg, and 6 on the bottom bar with a WLL of 600kg.

Each segment can fit 1 large cable or 2 small to medium sized cables and is designed to be lifted off the rack by a forklift, eliminating the need for manual labour. The whole rack is fitted with also fitted with forklift slots for ease of movement.

RESULT

Our first cable rack design was constructed and delivered to site on-time and on-budget.

Many sites throughout Western Australia are choosing to adopt our cable rack to ensure the safety of labourers and other site personnel and enhance organisation and efficiency.

Storage racks such as these can be modified to suit your specific requirements and are certified and compliant with the relevant Australian Standards.

Its perfect and fits in great. Thank you for your quick turn around once we placed the order.

– Jason (Karora Resources)