Degreaser Bunding

Large tanks of degreaser are regularly used in workshops to remove oil and grease from working areas and clean large mobile equipment.

Degreaser pods are often sold in 1000 litre tanks, requiring them to be stored in a safe and efficient manner. Tanks are also known to gather small leaks particularly at the degreaser spout point.

This increases the risk of slip hazards if an insufficient storage system is being used.

A valued client from a mine site in the Pilbara consulted with our team about this issue, saying that their method pictured to the right is insufficient in eliminating leaks.

SOLUTION

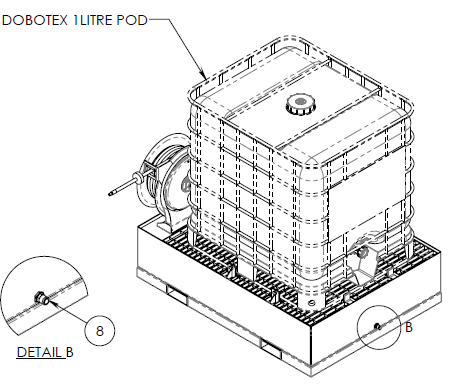

The client provided some ideas of how they wanted the bunding system to work and after a short design process our engineers presented the design pictured to the left.

The heavy-duty steel constructed degreaser bunding is designed to securely fit a 1000 litre pod.

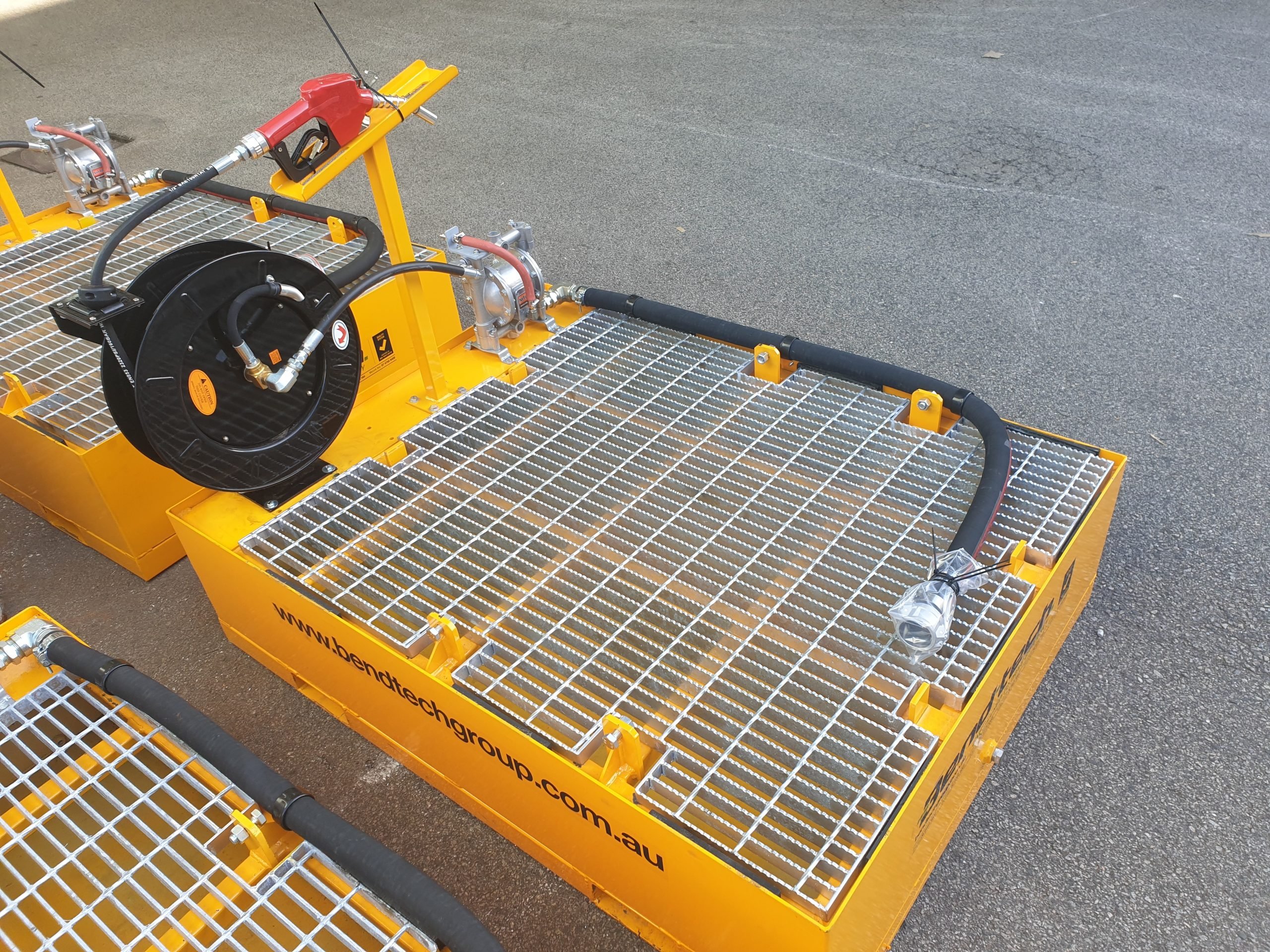

The bunding system features an air-operated diaphragm pump with a retractable hose reel and dispensing gun. A fluid level gauge is also fitted for conveniency.

Grafting allows for spillage to be collected into the bund where a drain bung allows for easy and efficient drainage.

Forklift slots are also fitted to allow for safe and convenient movement.

RESULT

Our valued client ordered three degreaser bunding systems which were fabricated and delivered to the Pilbara site on-time and on-budget.

Engineered safety solutions such as our degreaser bunding are not always a requirement, but they are setting the standard for workshop

and mining safety and efficiency. Read more about workshop safety and efficiency or see more of our case studies to get a better

understanding of how Bend-tech is transforming industry safety standards.