D10/11 Engine Bay Platform

Caterpillar D10’s and D11’s often require engine maintenance due to their heavy workloads and harsh mining conditions. The engine bay is located just above the tracks in an area that can be accessed just by standing on the tracks. But this is not a safe access solution.

Although this engine area may not be as high as some other mobile equipment, significant injuries could still occur if an operator were to fall. A safe access solution and work area is therefore essential for maintenance personnel.

SOLUTION

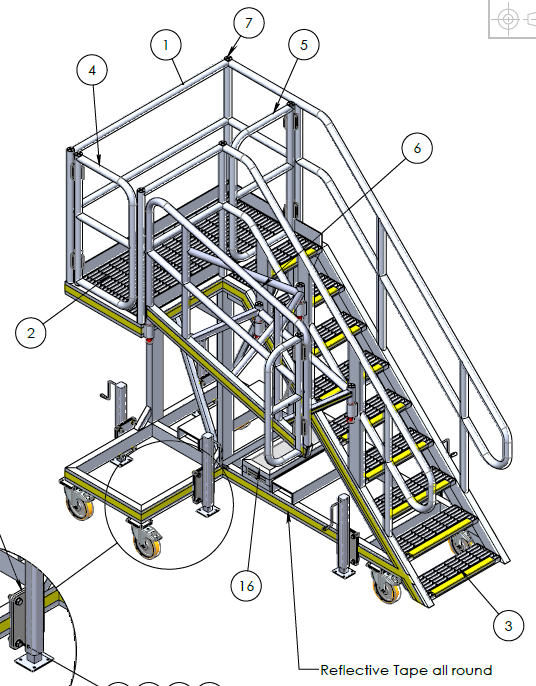

A Bend-tech representative was invited out to site to see the problem firsthand, where initial drawings and measurements were carried out. Our design and engineering team then put together the final draft pictured to the left.

The platform was designed to provide both safe access and a safe working area for personnel during engine maintenance. Personnel can reach the area safely up the non-slip stairway with step landings, while the detachable handrails with a swinging gate section provides complete fall protection in the work area.

Heavy-duty lockable caster wheels and jacking stands keep the platform firmly in place during maintenance. They also enhance movement and storage efficiency.

The platforms are a right-hand and left-hand set which enables access to both sides of the engine compartment safely.

RESULT

The D10/D11 engine bay platform is becoming a common piece of maintenance equipment in MEM workshops. It is also important to note that the platform is designed and engineered to be used both when the dozer blade is on or off. Andrew provides a summary of the D10 platform in his video to the right.

This is just an example of how we eliminate working at heights and fall hazards on mobile equipment, and maximise the safety of your maintenance personnel. Get in contact with the team today to discuss how we can transform safety in your operation.